Preparing a Proper Environment for Installation

Before installing the robot unit and robot controller, confirm that the operating environment is in conformity with each item of "SAFETY PRECAUTIONS,Installation Precautions 1". Also, take proper measures to protect the components from vibration.

In an inappropriate environment, the robot will not operate to its full capacity or performance, components may not last long, and unexpected failure may result.

Ambient Temperature and Humidity

Keep the ambient temperature between 0°C and 40°C during operation.

Keep the ambient humidity at 90% or below to prevent dew condensation.

Vibration

Do not install the robot in an environment where it will be exposed to excessive vibration or impact.

Connecting the Robot Unit and Robot Controller

Before delivery, the robot unit and the robot controller are adjusted to each other as a set. When two or more robots are to be used, use the robots and robot controllers that have been adjusted to each other as a set.

The robot unit and robot controller in a set are given the same serial number.

Installation Environment of the Robot Unit

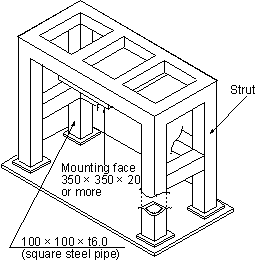

The table below lists the installation requirements for the robot unit. Prepare a highly rigid mount as shown below.

Do not electric-weld the equipment including the robot. A large current may flow through the motor encoder or robot controller resulting in a failure. If electric welding is required, remove the robot unit and the robot controller from the equipment beforehand.

| Item | Environments and Conditions |

|---|---|

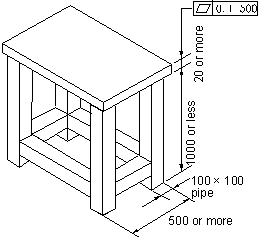

| Flatness of the mount | 0.1/500 mm (See the figure below.) |

| Rigidity of the mount | Use steel materials. (See the figure below.) |

| Installation type | Floor-mount or overhead-mount (Only for HMS) |

| Ambient temperature | During operation: 0 to 40ºC During storage and transportation: -10 to 60ºC |

| Humidity | During operation: 90% or less (No dew condensation allowed.) During storage and transportation: 75% or less (No dew condensation allowed.) |

| Vibration | During operation: 4.9 m/s2 (0.5G) or less During storage and transportation: 29.4 m/s2 (3G) or less |

| Altitude | During operation: 1,000 m or less |

| Safe installation environment | Refer to the SAFETY PRECAUTIONS, "Insuring the proper |

| Working space, etc. | • Sufficient service space must be available for inspection and disassembly. • Keep wiring space behind the robot, and fasten the wiring to the mounting face or beam so that the weight of the cables will not be directly applied to the connectors. Wiring space for motor and encoder cable must be at least

|

| Grounding conditions | Functional ground See the figure on"Grounding the Robot Unit" |

Robot Mount Sample for Floor-mount Type

|

- When the robot operates at high speed, the robot mount undergoes large reaction forces. The mount must be rigid enough so that it will not vibrate or be displaced due to reaction forces. It is also advisable to mechanically join the robot mount with heavy equipment.

- Some mounts may produce a resonance sound (howling). If this sound is loud, increase the rigidity of the mount or slightly modify the robot speed.

Robot Mount Sample for Overhead-mount Type

|

- When the robot operates at high speed, the top plate structure undergoes large reaction forces. The robot mount must be vibration-proof so that the top plate will not vibrate due to reaction forces. Also it must be designed to be separated from other top plate structures in the equipment.

- Some mounts may produce a resonance sound (howling). If this sound is loud, increase the rigidity of the mount or slightly modify the robot speed.