ID : 4765

Transporting the Overhead-Mount Type (HSS series)

This section gives the typical installation procedure of the robot unit.

- Since the robot unit weighs of HSS type approx. 25 kg (55 lbs), prepare a crane and forklift with a hoisting load of 0.2 ton or more.

- The overhead mounting job must be handled by at least two persons including a qualified operator for sling, crane and forklift operation.

- Be sure to put on a helmet, safety shoes, and gloves.

1

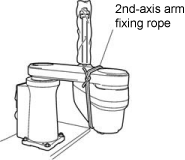

When unpacked, the overhead-mount robot unit is fastened with rope as shown below. Make sure that the robot's 2nd-axis arm cannot rotate.

NEVER remove the 2nd-axis arm fixing rope until the installation of the robot unit is completed.

This is to prevent the robot arm from rotating unexpectedly due to gravity.

2

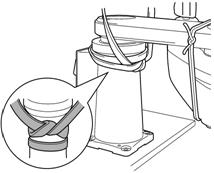

As illustrated below, wind the belt sling around the robot base two turns and make a knot on the side opposite to the power connector.

3

Load the eyes of the belt sling on the hook of the crane.

4

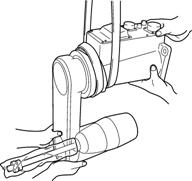

Remove the four bolts and release the robot unit from the pallet.

When worker A is removing those bolts, worker B should support the robot unit as shown below to prevent it from overturning.

5

While keeping the robot posture, slowly hoist the robot unit with the crane.

Before starting this job, make the work floor clear of obstacles.

6

If the crane hoists the robot unit until it may be turned upside down, stop the crane and have two workers turn the robot unit upside down, as shown below.

7

While having two workers keep the robot unit in the upside-down position, slowly hoist the robot unit with the crane so that the robot base comes into contact with the robot installation face of the overhead-mount frame. Secure the robot unit with four mounting bolts temporarily.

8

Firmly secure the robot unit, referring to "Securing the Robot Unit"

<For HSS Series> Tightening torque: 70 ±14 Nm

9

After completing bolting, unhook the belt sling from the crane and then remove the 2nd-axis arm fixing rope.

Store the 2nd-axis arm fixing rope for future removal of the robot unit.

ID : 4765