ID : 10163

Specifications of Robot Unit

This section describes specifications in the following subsections.

- Product Name and Model Type

- Motion, Outer Dimensions and Weight

- Environment Conditions of Installation Site

- Structure

- Equipment for Tool

Product Name and Model Type

| Product name | VMB-2515 | VMB-2518 |

|---|---|---|

| Model type |

|

|

Motion, Outer Dimensions and Weight

| VMB-2515 | VMB-2518 | |

|---|---|---|

| Maximum motion area |

1506mm (Point P: 4th, 5th, 6th axis center) |

1804mm (Point P: 4th, 5th, 6th axis center) |

| Maximum motion range |

|

|

| Overall arm length |

710mm (first arm) + 685mm (second arm) = 1395mm |

860mm (first arm) + 835mm (second arm) = 1695mm |

| Maximum payload |

25 kg |

|

| Maximum allowable moment |

|

|

| Maximum allowable moment of inertia |

|

|

|

Position repeatability |

In each of X, Y and Z directions: ±0.05 mm (The position repeatability is the value at constant ambient temperature). |

|

|

Maximum composite speed |

13,370 mm/s | 14,000 mm/s |

| Outer dimensions | Refer to the drawing. | Refer to the drawing. |

| Weight | Approx. 230 kg | Approx. 250 kg |

*1 : 1st axis maximum motion angle when installing on the wall or tilted surface

| Model type | Tilt angle | Motion range | Model type | Tilt angle | Motion range | |

|---|---|---|---|---|---|---|

| VMB-2515 | 0° to 35° | ±170° | VMB-2518 | 0° to 30° | ±170° | |

| 35° | ±63° | |||||

| 40° | ±66° | 40° | ±52° | |||

| 45° | ±55° | 45° | ±45° | |||

| 50° | ±48° | 50° | ±41° | |||

| 55° | ±44° | 55° | ±37° | |||

| 60° | ±41° | 60° | ±35° | |||

| 65° | ±38° | 65° | ±33° | |||

| 70° | ±37° | 70° | ±31° | |||

| 75° | ±35° | 75° | ±30° | |||

| 80° | 80° | |||||

| 85° | ±34° | 85° | ±29° | |||

| 90° | 90° | |||||

| 95° | 95° | |||||

| 100° | ±35° | 100° | ±30° | |||

| 105° | 105° | |||||

| 110° | ±37° | 110° | ±31° | |||

| 115° | ±38° | 115° | ±33° | |||

| 120° | ±41° | 120° | ±35° | |||

| 125° | ±44° | 125° | ±37° | |||

| 130° | ±48° | 130° | ±41° | |||

135° |

±55° | 135° |

±45° | |||

| 140° | ±66° | 140° | ±52° | |||

| 145° to 180° | ±170° | 145° | ±63° | |||

| 150° to 180° | ±170° | |||||

| For details, refer to the graph. | For details, refer to the graph. | |||||

Environment Conditions of Installation Site

| VMB-2515 | VMB-2518 | |||

|---|---|---|---|---|

| Ambient temperature | In operation : 0 to 40°C In storage/ In transportation : -10 to 60°C |

|||

| Relative humidity | In operation : 20 to 90%RH (no dew condensation allowed) In storage/ In transportation : 40 to 75%RH (no dew condensation allowed) |

|||

| Vibration | In operation : 4.9 m/s² (0.5G) or less In storage/ In transportation : 29.4 m/s² (3G) or less |

|||

| Altitude | In operation : 1,000m or less |

|||

| Materials of the mount | Use steel materials. | |||

| Electrical noise | The robot should not be installed in any environment where;

|

|||

| Environment conditions | For Standard Type and Cleanroom TypeThe robot should not be installed in any environment where;

|

|||

For Protected TypeThe robot should not be installed in any environment where;

|

||||

Structure

| VMB-2515 | VMB-2518 | |

|---|---|---|

| Position detection | Absolute encoder | |

| Drive motor | AC servomotors for all joints | |

| Rated output of the motors |

|

|

| Brake |

|

|

| Degree of protection |

|

|

| Clean level | Cleanroom type: ISO5 |

|

| Noise (Equivalent continuous A-weighted sound pressure level) |

75dB | |

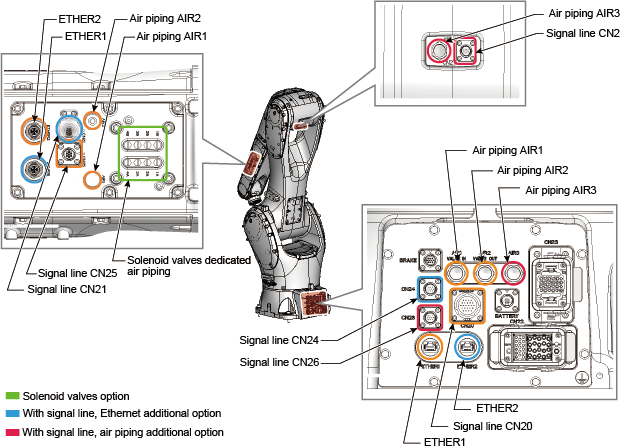

Equipment for Tool

| VMB-2515 | VMB-2518 | ||

|---|---|---|---|

| Group 1 (*1) | Without solenoid valves option |

|

|

| With solenoid valves option (standard type, protected type) |

|

||

| With solenoid valves option (cleanroom type) |

|

||

| Group 2 (*1) | Without signal line, Ethernet additional option |

|

|

| With signal line, Ethernet additional option |

|

||

| Group 3 (*1) | Without signal line, air piping additional option |

|

|

| With signal line, air piping additional option |

|

||

| Air source of air piping | Operating pressure | 0.20 to 0.39 MPa | |

| Maximum allowable pressure | 0.49 MPa | ||

| *1: |

The specification of the equipment for tool is the combination of the specifications of group 1 to 3. For example, if group 1 is "with solenoid valves option (standard type, protected type)" and group 2 is "with signal line, Ethernet additional option" and group 3 is "without signal line, air piping additional option", the total specification is as below.

|

| *2: |

Do not apply the electrical current more than the allowable current of the signal line. |

ID : 10163

- Related Information

- Coding Information of Robot Model