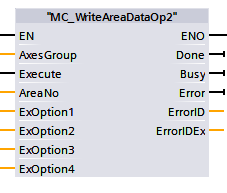

MC_WriteAreaDataOp2

To specify the options of specified detection area, such as exteded-joint.

| Graphic expression |

FB No. |

FB category |

|

FB2133 |

Non motion |

Input parameter

| Parameter name |

Data type |

Valid range |

Default |

Omission (*) |

| AxesGroup |

Integer |

1 or larger |

1 |

No |

- Robot number

- Specify an element number for the variable "Robots[n]" (variable in the data block "DB_DENSO_ROBOTS (DB2990)") mapped to the controlled robot (robot controller).

If a specified value exceeds the valid range, the CPU (PLC) stops.

The maximum valid range value is the maximum element number of the variable "Robots[n]". The default maximum element number is 10 but can be increased or decreased by the user.

|

| Execute |

Boolean |

|

False |

No |

- Execution start

- When the parameter is changed from False to True, this FB is executed.

|

| AreaNo |

Integer |

0 to 31 |

0 |

No |

- Area number

- Specify an area number.

|

| ExOption1 |

Array[0..2] of Real |

Real[0] |

5 to 8 |

0 |

Yes |

| Real[1] |

- |

0 |

| Real[2] |

0 or larger |

-1 |

- Exteded-joint 1 option 1 (Axis number)

- Specify the number of extended-joint.

- Exteded-joint 1 option 2 (Position)

- Specify the position to detect.

- Exteded-joint 1 option 3 (Error range)

- Designate tolerable error range (angle). Unit is degree.

When "-1" is entered, figure is not checked.

|

| ExOption2 |

Array[0..2] of Real |

Real[0] |

5 to 8 |

0 |

Yes |

| Real[1] |

- |

0 |

| Real[2] |

0 or larger |

-1 |

- Exteded-joint 2 option 1 (Axis number)

- Specify the number of extended-joint.

- Exteded-joint 2 option 2 (Position)

- Specify the position to detect.

- Exteded-joint 2 option 3 (Error range)

- Designate tolerable error range (angle). Unit is degree.

When "-1" is entered, figure is not checked.

|

| ExOption3 |

Array[0..2] of Real |

Real[0] |

5 to 8 |

0 |

Yes |

| Real[1] |

- |

0 |

| Real[2] |

0 or larger |

-1 |

- Exteded-joint 3 option 1 (Axis number)

- Specify the number of extended-joint.

- Exteded-joint 3 option 2 (Position)

- Specify the position to detect.

- Exteded-joint 3 option 3 (Error range)

- Designate tolerable error range (angle). Unit is degree.

When "-1" is entered, figure is not checked.

|

| ExOption4 |

Array[0..2] of Real |

Real[0] |

5 to 8 |

0 |

Yes |

| Real[1] |

- |

0 |

| Real[2] |

0 or larger |

-1 |

- Exteded-joint 4 option 1 (Axis number)

- Specify the number of extended-joint.

- Exteded-joint 4 option 2 (Position)

- Specify the position to detect.

- Exteded-joint 4 option 3 (Error range)

- Designate tolerable error range (angle). Unit is degree.

When "-1" is entered, figure is not checked.

|

(*) : For some parameters, entries can be omitted.

- Yes : Entry can be omitted.

- No : Entry required always.

Output parameter

| Parameter name |

Data type / Description |

| Done |

Boolean |

- Execution completion confirmation

- True : This FB execution is completed.

False : This FB execution is not completed.

|

| Busy |

Boolean |

- Processing status of this FB

- True : Being executed.

False : Not being executed.

|

| Error |

Boolean |

- Error presence

- True : This FB ended abnormally.

False : This FB ended successfully.

|

| ErrorID |

Word |

- Error location

- 2800 (hexadecimal) : The error occurred in the PLC program.

2801 (hexadecimal) : The error occurred in the robot controller.

|

| ErrorIDEx |

DWord |

- Error Code

- This is a number to identify the error description.

For details, refer to "Error code list".

|

Function description

-

Attention

If you the change work coordinates during area interference (area check) function enabled state, depending on the system, it will take up to 10ms before the new work coordinate is reflected into the interference check area judgment.

To use the new work coordinate for the area interference check without fail, before you change the work coordinate, set the robot so that the area interference does not occur (such as stop the robot motion), wait until the new work coordinate is applied to the system, and restart the robot.