ID : 4655

Daily Inspections

Before starting operations, check the items listed below every day.

Inspections to Be Made with the Power OFF

| Check: | How to check: | Criterion | What to do: (See note below.) |

|---|---|---|---|

| Connectors | Visually | No looseness, disengagement or dirt. | Engage the parts properly and clean them. |

| Cables | Visually | Free of damage or gouges. | Repair or replace. |

| Brake release switch on the UL-Listed robot units | Check for looseness. | No looseness. | Tighten up. |

| Bellows (on the Z-axis of dust- & splash-proof type and clean room type) | Visually | No breakage. | Inspect and repair. |

| Robot unit (except for lubrication points) | Visually | No grease leak. | Wipe off grease. |

| Hole that goes through the z-axis shaft | Visually | No drips of grease or rust preventive oil. | Wipe off grease or rust preventive oil. |

Inspections to Be Made with the Power ON

| Check: | How to check: | Criterion | What to do: (See note below.) |

|---|---|---|---|

| LCD on the teach pendant | Visually | Properly displayed. | Repair or replace. |

| Pilot lamps on the robot controller | Visually | Should light. | Repair or replace. |

| Cooling fan in the robot controller | Hold up a hand to the exhaust port and check the wind is blowing off. | Should work properly. | Repair or replace. |

| EMERGENCY STOP button on the teach pendant, the mini pendant or the emergency stop switch box | Press the EMERGENCY STOP button. | The robot should come to an emergency stop. | Repair or replace. |

| Safety door | Operate the safety door switch and open the switch-wiring door. | The robot should come to an emergency stop. | Inspect and repair. |

| Motor ON lamp on the UL-Listed robot units | Visually | It should light when the motor is ON. | Inspect and repair. |

Some repair and replacement jobs, shown in "What to do:" column, may involve special work. Contact the Denso service representative.

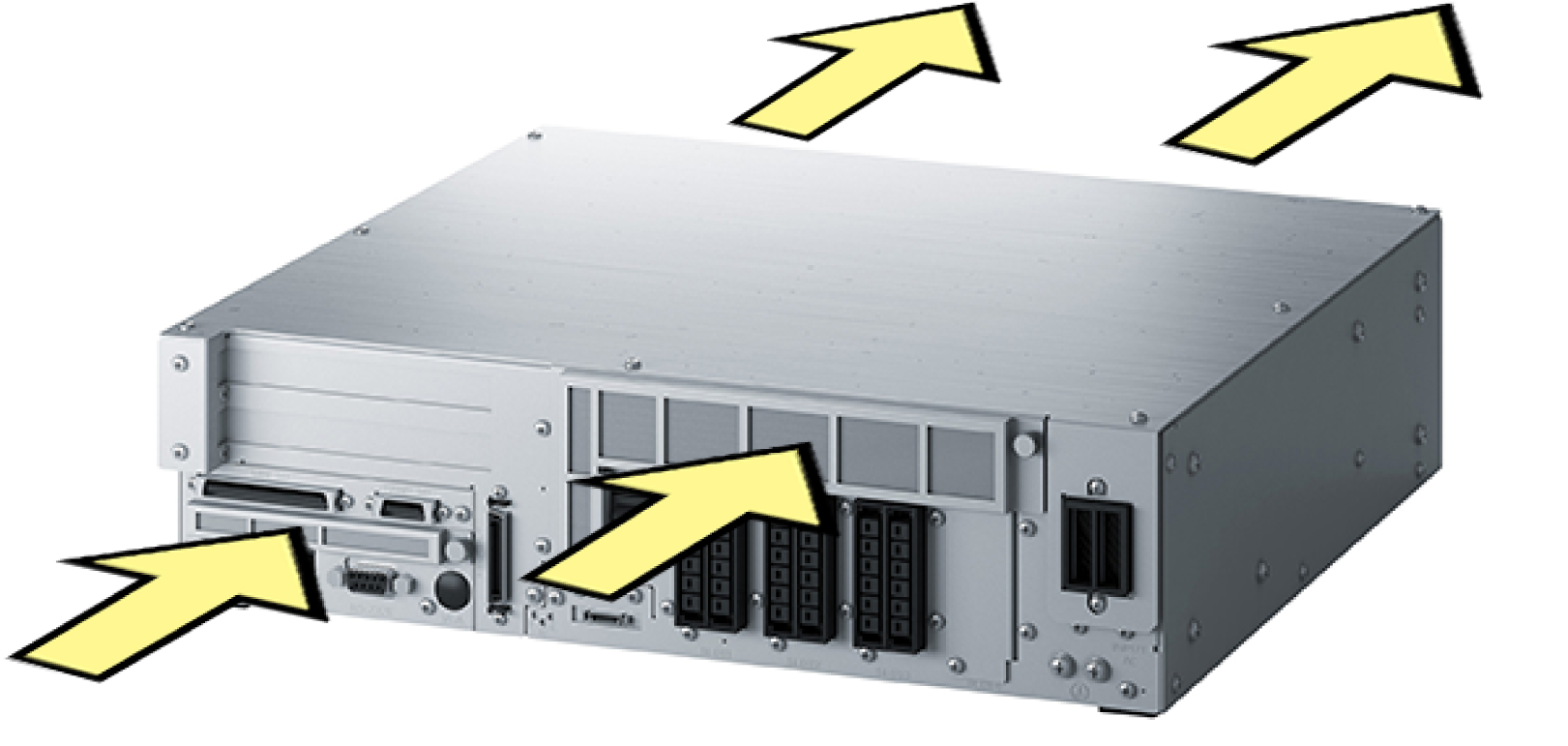

Normal Operation of Cooling Fan

The normal operation of the cooling fan is as shown in the next figure.

|

ID : 4655