ID : 6416

Configurators

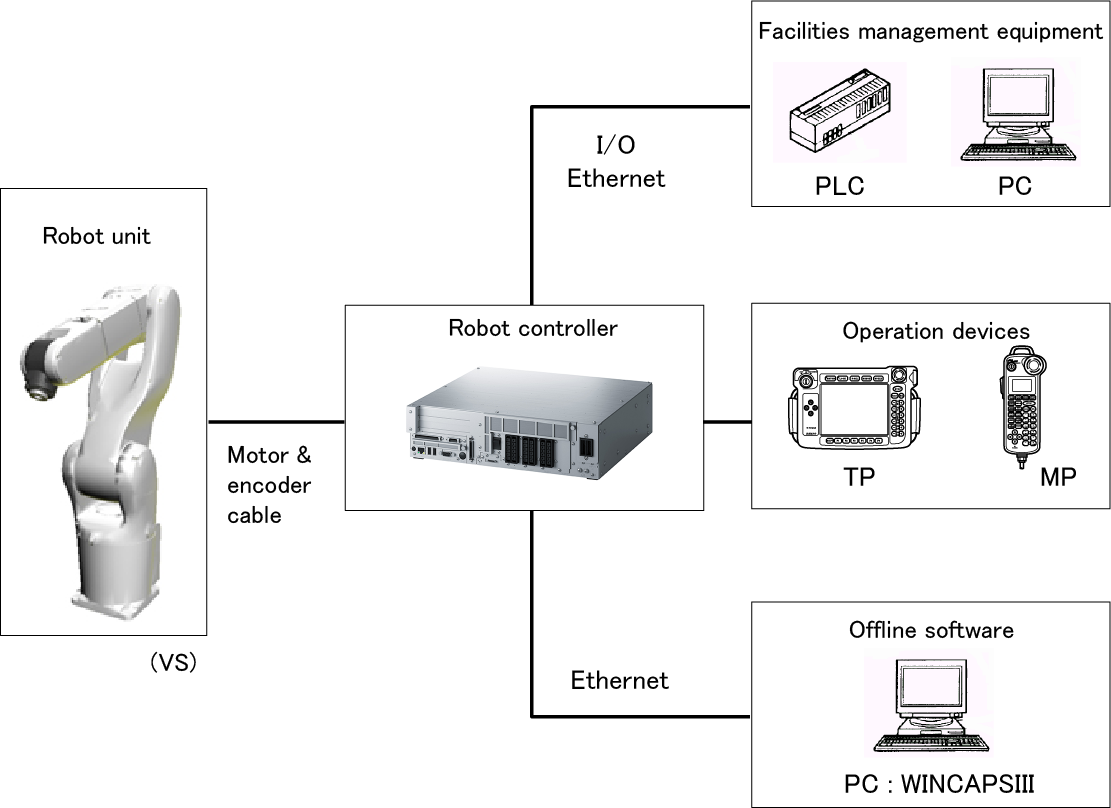

The whole configuration of the robot system is shown below.

Robot Unit

This is an industry robot that drives the arms with the motors to assemble and transport workpieces. Hands or other end effectors should be attached to the flange by the customer.

Robot Controller

The controller controls the motion of the robot unit according to programs built with signals sent from the connected facilities management equipment.

It also allows the customer to teach the robot unit by operating it with any of the operation devices.

Operation Devices

The operation devices are used to manually operate the robot unit or make various settings.

For details about hardware, refer to the Operation Guide. For instructions on how to operate these devices, refer to the "TEACH PENDANT OPERATION GUIDE " and "MINI PENDANT OPERATION GUIDE".

Teach Pendant (TP)

The teach pendant is a multifunctional operation device that enables robot operation, teaching, mode switching, programmed start, programming, and all settings.

The teach pendant can also be used as an operation panel created by the teach pendant panel editor.

Mini-Pendant (MP)

The mini-pendant is a simplified operation device that enables robot operation, teaching, mode switching, programmed start, and a part of settings.

Offline Software

The software enables backing up of project data in the controller and editing, management, movement simulation of programs. WINCAPSIII is an offline software designed for the Denso robot system. The trial version comes with the robot system at no extra charge. For details, refer to the WINCAPSIII GUIDE.

Facilities Management Equipment

The management equipment is a system that the customer sets up for managing the facilities. Denso robots can be linked with it via the CC-Link, Ethernet/IP, and other various networks.

ID : 6416