ID : 10843

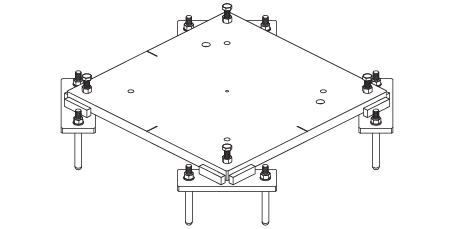

Level-adjustable Robot Fixing Plate

This is the robot fixing plate to install between the robot mounting surface and the concrete surface.

You can set the necessary levelness by the level adjustment function.

Components

- Level adjusting plate (quantity : 1)

- Base plate (quantity : 4)

- Positioning plate (quantity : 8) (*1)

- Hexagon head bolt M20 × 100mm, strength class: 8.8 (quantity : 4) (*2)

- Hexagon nut M20 × 8mm (quantity : 4) (*2)

*1 : After level adjustment, weld the base plate and the level adjusting plate.

*2 : This is for level adjustment.

Weight

About 220 kg

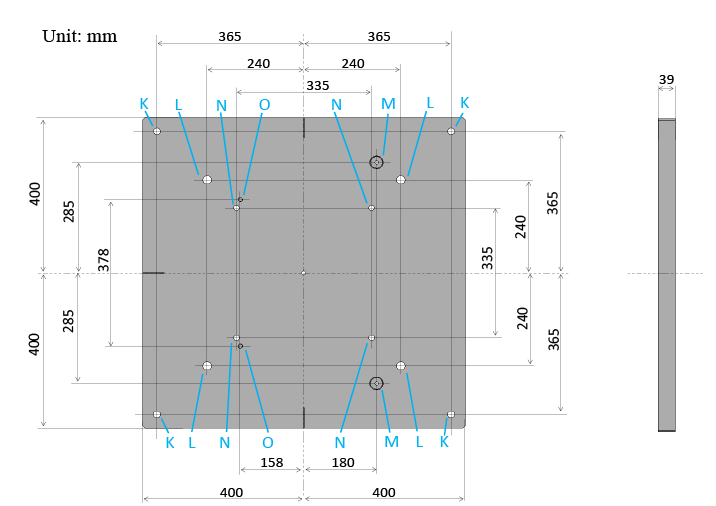

Plate Installation Hole

K : For chemical anchor

L : For robot fixing bolts (for VLA series)

M : For the dowel pin (for VLA series)

N : For robot fixing bolts (for VMB series)

O : For the dowel pin (for VMB series)

Installation Procedure

Recommended Tool and Equipment

- Chemical anchor (*1)

- Drilling machine

- Drill bit for holes ø9 and ø24

- Angle grinder

- High precision level gauge

- Torque wrench with sockets and bits

- Arc welding machine

- Eyebolt M24 (quantity : 4)

- Mortar for metal (*2)

*1 : The following shows recommendations. In addition to the procedure below, handle the chemical anchor according to the instruction manual that came with the chemical anchor you purchased.

| Part name | Manufacturer | Part No. | Hole dimension and diameter | Quantity |

|---|---|---|---|---|

| Chemical capsule | HILTI | HVU M20x170 | ø24x170mm | 8 |

| Threaded anchor rod | HAS-E M20x170/48 | 8 |

*2 : To avoid micromovement of the plate caused by reaction force repeatedly generated by the robot during robot operation, it is recommended to lay the mortar for metal on the concrete surface and make the installation surface horizontal.

Preparation before Installation

1

Put the mark of two vertical axes on the floor which the robot will be installed.

2

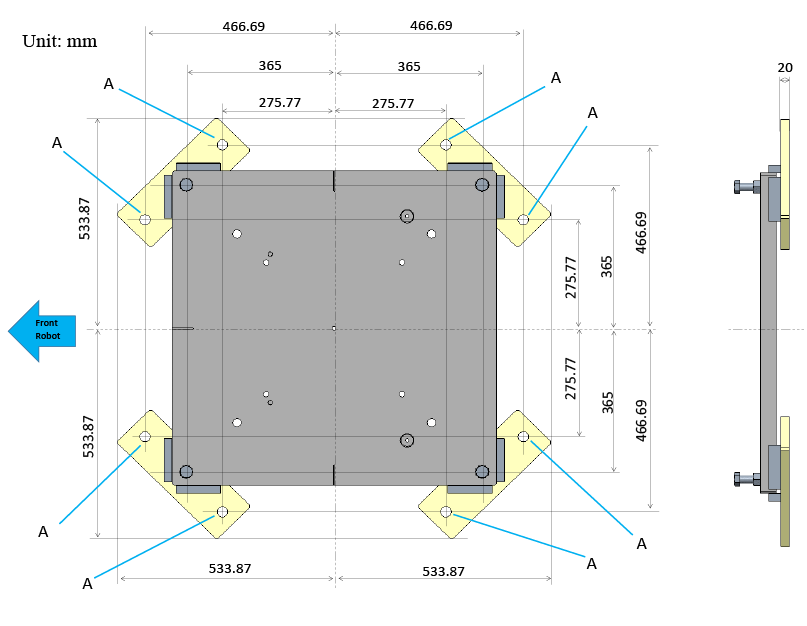

Mark the position of the hole (A) to place the chemical capsules.

3

Pre-drill the floor surface using the drilling machine and the drill bit ø9 (depth 170 mm).

4

Drill the floor surface using the drilling machine and the drill bit ø24 (depth 170 mm).

- Make sure to carry out the drilling vertically to the floor.

- Do not use water for the drilling. The hole must be dry.

5

Remove all the residual material by a vacuum cleaner and make the inside of the holes perfectly clean.

6

Insert the chemical capsule into the hole.

7

After inserting the threaded anchor rod, stir the chemical capsule by rotation and striking to ensure that the chemical components are in contact with the screw.

8

Wait for that the chemical capsule acts, fixes the rod and the rod itself is firmly combined to the floor. The waiting time is about 5 hours.

9

Clean the installation surface on the floor which the robot fixing plate will be placed.

Installation Procedure

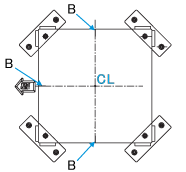

There are three notches (B) on the plate. Axial intersection of notches is defined as the position of the robot 1st axis (reference CL). In correspondence with this position on the plate, there is a dowel pin hole.

1

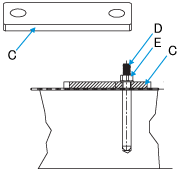

After spreading the mortar for metal (recommended step), install four base plates (C) so that the anchor rods (D) can be inserted into the holes in the base plate.

2

Fix four base plates on the floor. Tighten the nut (E) of the anchor rod with tightening torque 150Nm.

3

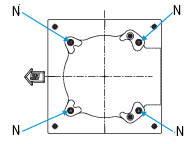

Insert four eyebolts into the holes (N) on the level adjusting plate .

4

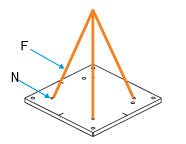

Sling the level adjusting plate by means of four sling belts (F) (minimum length: 1 m).

5

Lift the plate (about 220 kg) using a lifting device.

6

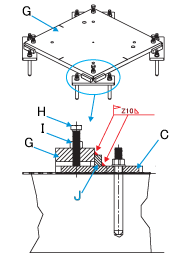

Place the level adjusting plate (G) on the four base plates (C) fixed on the floor.

7

Level the plate using the hexagon head bolts (H) so that levelness of the robot mounting surface is ± 0.5/1000mm or less.

8

Once the proper levelness is obtained, screw the hexagon nut (I).

9

Place the positioning plate (J).

10

Carry out the electric welding of the positioning plate (J) to the joint part of the base plates and the level adjusting plate. Carry out the electric welding along the entire length of the positioning plate.

For the bead welding of the corner, observe all the technical precautions needed to carry out the proper welding of the joint.

If it is not welded precisely, the robot cannot be fixed correctly. It may cause malfunctions during robot motion and operators may be in dangerous situations.

This completes installation of the robot fixing plate.

ID : 10843