ID : 10953

How to Design a Servo Mechanism

This section describes how to design the servo mechanism using the auxiliary axis function.

Example of the Mechanism

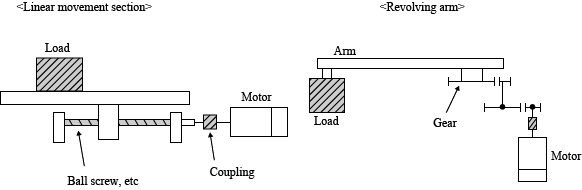

The mechanism is classified into a linear movement section and a revolving arm section as shown in the figure below.

Selection of the Drive System

An appropriate control cannot be performed if a rapid torque fluctuation occurs due to stick slip or the like. The typical examples of appropriate and inappropriate drive systems are as shown below:

| Drive System | Conditions | Adequacy |

|---|---|---|

| Ball screw | Grinding : Backlash small | A |

| Rolling : Backlash large (Control instable) | B | |

| Gear | Grinding : Accuracy grade 1 or higher : Backlash small | A |

| Cutting : Accuracy grade 3 or higher : Backlash medium | B | |

| Cutting : Accuracy grade 4 or higher : Backlash large | C | |

| Screw shaft | Friction large | C |

| Harmonic drive | Friction large (Care for selection) | B |

| Slide section bearing | Linear motion bearing | A |

| LM guide | A | |

| Slide bearing : Friction large | C | |

| Seal, packing | When the calculated torque is 20% or less of the rated motor torque. (The calculated torque mentioned here indicates the friction of the drive part that is converted into the torque value applied to the motor shaft.) | B |

| When the calculated torque is more than 20% of the rated motor torque. (The calculated torque mentioned here indicates the friction of the drive part that is converted into the torque value applied to the motor shaft.) | C |

A : Appropriate

B : This indicates the need for the careful selection of components and the possibilities of unstable system control and a system with large backlash.

C : Inappropriate

ID : 10953