ID : 886

Precautions about CALSET

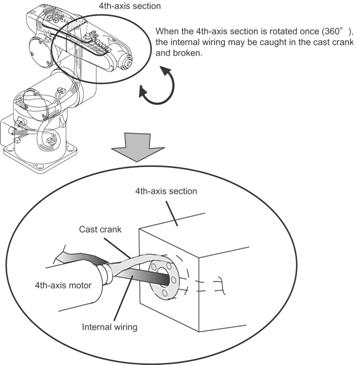

Robots in the VM-6083/VM-60B1 series launched have no mechanical stop on the 4th-axis.

If the 4th-axis CALSET position is wrongly set by one rotation (360°) while CALSET is being carried out, the internal wiring may be caught in the crank and broken. To carry out CALSET with a robot with no 4th-axis mechanical stop, check the normal 4th-axis position first as described below.

|

Checking of 4th-axis Position before Carrying Out CALSET

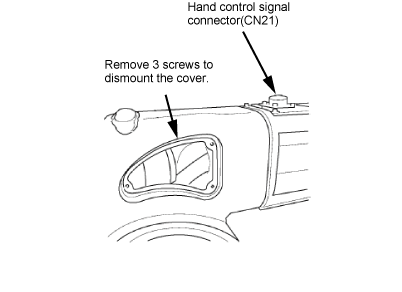

- Manually move the 4th-axis section until the hand control signal connector comes to the upper side.

-

Dismount the cover from the second arm so that the internal wiring can be checked.

VM-6083, VM-60B1 (with no 4th-axis mechanical stop) -

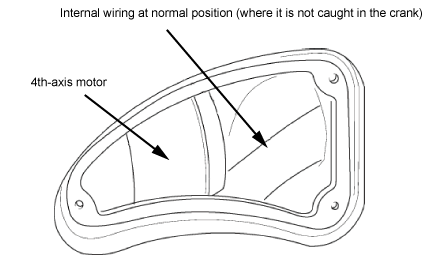

Check that the 4th-axis section is at a designated position.

(The hand control signal connector (CN21) of the second arm comes to the upper side and the internal wiring is not caught in the crank at this time.)

Checking the 4th-axis position for VM-6083/VM-60B1

-

When the 4th-axis section is not at the normal position, manually move it to a designated position.

Preparation before carrying out CALSET is finished now.

If the step is omitted, the 4th-axis CALSET position may be mistaken by one rotation (360°). The internal wiring may be caught in the crank and broken in such a case.

ID : 886