ID : 2447

Notes for Wiring and Piping Through a Hollow in the Z-axis Shaft

The Z-axis shaft has a hollow through which you may make wiring and piping from the hand control signal connector or air piping joints on the top of the 2nd arm.

In this wiring and piping, check that:

- Be sure to mount a stopper with wiring protection (option) and a wiring protection kit (option of the bellows type, dust- & splash-proof type, cleanroom type, H1 grease type) as the following shows.

- When the robot is in motion, the wiring and piping do not become taut or interfere with other sections.

- During up- or down-movement of the Z-axis, the wiring and piping inside the hollow do not become taut or interfere with other sections.

- Making the wiring and piping able to be pulled out through the hollow makes maintenance easy.

For information about the part number of the stopper with wiring protection and the wiring protection kit, please refer to "Options for Robot Unit".

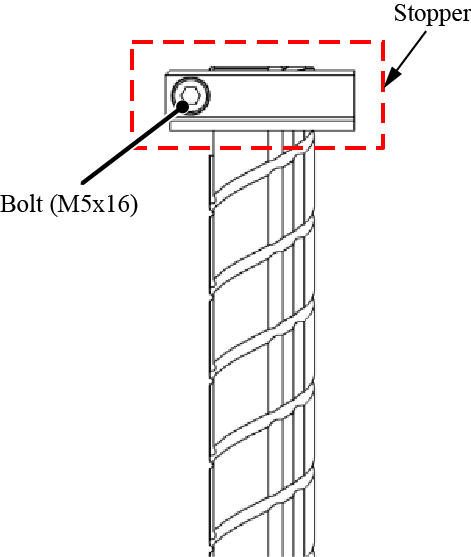

Installation of Stoppers

1

Remove a stopper bolt (M5 x 16) mounted on the top of the Z-axis shaft.

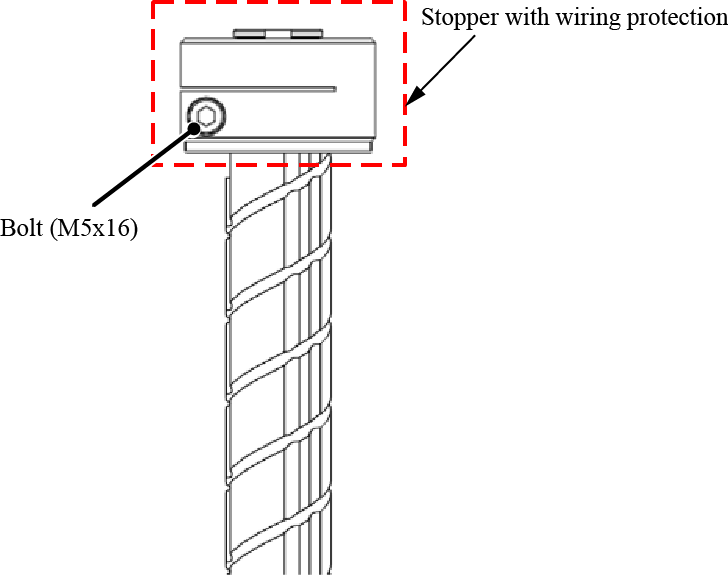

2

Insert the stopper with wiring protection into the shaft end, and then tighten it with a bolt (M5 x 16).

(Tightening torque: 5.9±0.59Nm)

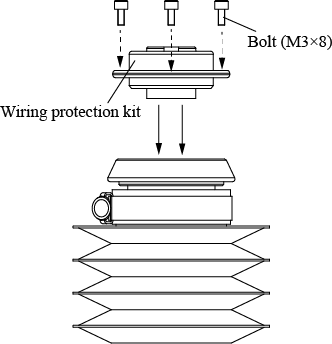

Installation of Wiring Protection Kit (Bellows Type, Dust- & Splash-proof Type, Cleanroom Type, H1 Grease Type)

1

Mount the wiring protection kit on the top of Z-axis shaft and fix it with bolts (M3 x 8).

(Tightening torque:1.6±0.16Nm)

ID : 2447