ID : 4650

CALSET

What Is CALSET?

Calibrating the relationship between position information recognized by the robot controller and the actual position of the robot arm is called CALSET.

CALSET uses a previously determined axis position where an axis can be secured. It creates calibration data (CALSET data) that matches the actual axis position (CALSET position) with the encoder value. The angle of the CALSET position is saved in the robot controller as a RANG value.

The CALSET data is different on each robot.

CALSET must be performed when any of the motors is replaced or the encoder backup battery goes dead so that the position-related data retained in the encoder is lost.

CALSET data should be managed by the customer. Back up the CALSET data periodically, referring to "Backing up Projects ".

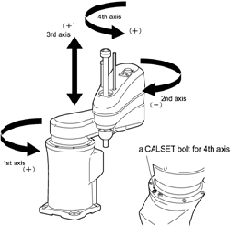

Factory Dfaults of CALSET Position

Location |

1st axis | Turning end in the positive direction (counterclockwise end when viewed from the top) |

|

|---|---|---|---|

| 2nd axis | Turning end in the negative direction (clockwise end when viewed from the top) |

||

| 3rd axis | Upper end (in the positive direction) |

||

| 4th axis | Turning end in the positive direction (counterclockwise end when viewed from the top) |

||

External appearance |

HM series

|

HMS series

|

|

Preparation for CALSET

Press each of the 1st- to 4th-axes against the associated mechanical ends by hand to get the actual positions.

CALSET requires some space for bringing each axis into contact with the mechanical end.

- When CALSETing, move the axis to be CALSET in the vicinity of the mechanical end, release the brake, and bring the axis into contact with the mechanical end. When bringing the 3rd axis (Z-axis) into contact with the mechanical end, be careful not to let your fingers get caught in the geared part of the rack.

- After CALSET, confirm in the manual mode that each axis stops at the software motion limit before coming into contact with the mechanical end.

- In automatic operation, start to run the robot at low speed. Ensuring safety, gradually increase the speed. It makes adjustment easy.

- Position-related data in some programs made before CALSET may vary somewhat after CALSET.

When CALSETing the 4th axis of the dust- & splash-proof type, you need to pull down the lower bellows for setting the CALSET bolt.

CALSET Procedure

1

Release the brake of an axis to be CALSET and move the axis to the CALSET position.

2

Use the teach pendant to select CALSET.

For detailed operation procedure, refer to "Displaying CALSET Operation Menu ".

ID : 4650

- Related Information

- Mounting CALSET Bolts on the 4th Axis