ID : 4856

CALSET

What Is CALSET?

Calibrating the relationship between position-related information recognized by the robot controller and the actual position of the robot unit is called CALSET.

CALSET must be performed when the motor is replaced or when the encoder backup battery goes dead and the position-related data retained in the encoder is lost as a result.

After calset is completed, the calibrated data of the robot unit will be stored in the robot controller. This data is called CALSET data which is different on each robot.

Back up the CALSET data periodically, referring to "Backing up Projects ".

CALSET Positions (by factory default)

| Robot series | XR-G Series | |

|---|---|---|

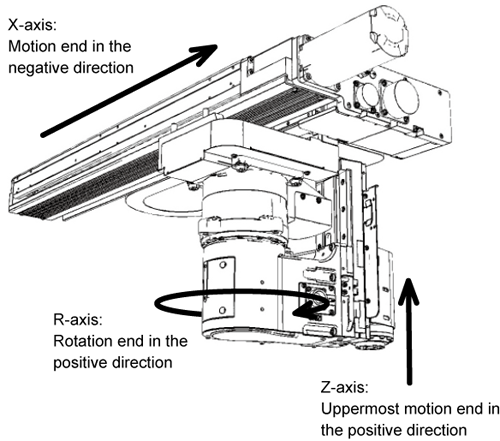

| Location | X-axis (1st axis) | Motion end in the negative direction |

| R-axis (2nd axis) | Rotation end in the positive direction | |

| Z-axis (3rd axis) | Uppermost motion end (in the positive direction) | |

| T-axis (4th axis) | Rotation end in the positive direction set by the CALSET jig. (Refer to"Mounting the CALSET jig on the 4th axis (T-axis)") | |

|

|

||

If the R-axis mechanical end position has been changed by the customer, revert it to the 180° position (factory default) before CALSETing.

CALSET Procedure

1

Release the brake of an axis to be CALSET and move the axis to the CALSET position.

2

Use the teach pendant to select CALSET.

Refer to the "Displaying CALSET Operation Menu " of TEACH PENDANT OPERATION GUIDE.

ID : 4856

- Related Information

- Mounting the CALSET jig on the 4th axis (T-axis)