ID : 1929

Installation Precautions 2

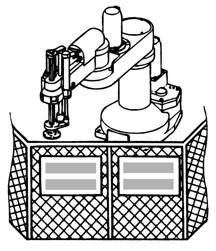

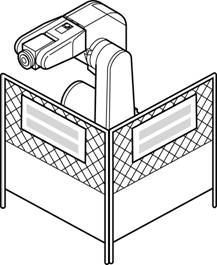

Setting-up a Safety Fence

A safety fence should be set up so that neither operator nor third person can easily enter the safeguarded space. Safety fences should be set up based on user's risk assessment.

Example

- The fence should be constructed so that it cannot be easily moved or removed.

- The fence should be constructed so that it cannot be easily damaged or deformed through external force.

- Establish the exit/entrance to the fence. Construct the fence so that neither operator nor third person can easily get past it by climbing over the fence.

- The fence should be constructed to ensure that it is not possible for hands or any other parts of the body to get through it.

- Install a door interlock device on the door in the fence.

To prevent workers from being trapped inside the safety fence, ensure that the door interlock device can be easily released from the inside of the safety fence regardless of whether the power is on or off. - If you run the robot for commissioning without setting up a fence, place an observer in a position outside the safeguarded space and where the observer can watch the movement of the robot, and ensure the observer is committed to the monitoring tasks.

Setting the Robot's Motion Space

The area required for the robot to work is called the robot's operating space.

If the robot’s motion space is greater than the operating space, it is recommended that you set a smaller motion space to prevent the robot from interfering or disrupting other equipment.

No Robot Modification Allowed

Never modify the robot unit, robot controller, teach pendant or other devices.

Cleaning of Tools

If your robot uses welding guns, paint spray nozzles, or other end-effectors requiring cleaning, it is recommended that the cleaning process be carried out automatically.

Lighting

Sufficient illumination should be assured for safe robot operation.

Protection from Objects Thrown by the End-effector

If there is any risk of workers being injured in the event that the object being held by the end-effector is dropped or thrown by the end-effector, consider the size, weight, temperature and chemical nature of the object and take appropriate safeguards to ensure safety.

Affixing the Warning Label

Place the warning label pack¬aged with the robot on the exit/entrance of the safety fence or in a position where it is easy to see.

Posting the Moving Directions of All Axes

Post a notice showing axes names and moving directions in a visible location on the robot unit. The posted moving directions should match the actual directions. No posting or wrong direction posting may result in bodily injuries or property damages due to incorrect operation.

Changing the Configuration

When the components of the robot system or optional devices (including hardware software) have been changed or added, carry out necessary tests or inspections of safety functions.

ID : 1929