ID : 2460

Semiyearly Inspections

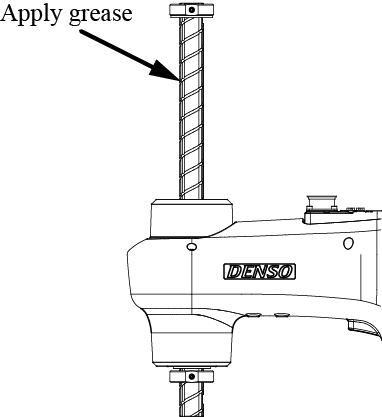

Apply the specified grease to the whole Z-axis shaft as shown below every six months.

When moving the Z-axis shaft, be careful not to let the shaft drop or your finger get caught in it.

| No. | Grease points | Grease part No. | Amount of grease | Remarks |

|---|---|---|---|---|

| 1 | Z-axis shaft | 410971-036* | 1 to 2 g | Apply the grease to the whole Z-axis shaft. |

| 2 | 410971-040* | 1 to 2 g | Apply the grease to the whole Z-axis shaft. (Exclusive to H1 grease type) |

|

|

|

||||

- Move the shaft a few times, and then wipe off the grease accumulated in the upper and lower end.

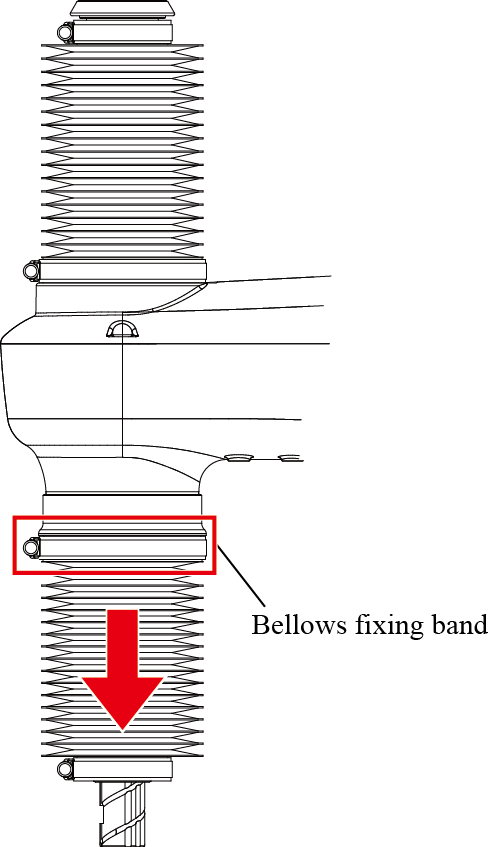

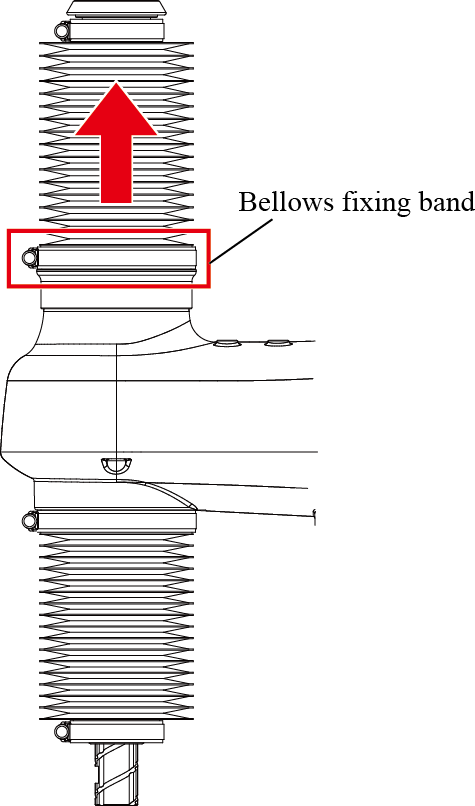

- When applying grease for the bellows type, dust- & splash-proof type, cleanroom type, and H1 grease type robot, the operation differs depending on the installation type (floor-mount or overhead-mount type).

Floor-mount Remove the bellows fixing band, and then press down the lower bellows.

Overhead-mount Remove the bellows fixing band, and then pull up the upper bellows.

Precautions for Handling of the Grease

- Inhalation: Move affected person into fresh air and keep warm. If breathing is difficult, give oxygen. Get medical attention if any discomfort continues.

- Skin contact: Remove contaminated clothing. Wash with soap and water. Get medical attention if irritation persists after washing.

- Eye contact: Flush thoroughly with water. If irritation occurs, get medical assistance. Make sure to remove any contact lenses from the eyes before rinsing.

- Ingestion: Immediately rinse mouth and drink plenty of water. Never give anything by mouth to an unconscious person. Get medical attention if any discomfort continues.

ID : 2460