ID : 6521

Instructions for Using Splash-proof Connector Sets (for CN20,CN21)

The splash-proof connector sets for CN20 and CN21 assure the splash-proofness as long as they are properly assembled and connected.

When using those connector sets, be sure to observe the following notes.

- The degree of protection of the splash-proof robot unit is assured as long as the splash-proof connectors are joined with connectors CN20 and CN21 on the robot unit. If there is no connection on CN20 and CN21, the splash-proof rating is not assured.

- Use a sheathed cable for a splash-proof connector. Using an unsheathed cable cannot assure the splash-proof rating.

- Each connector set contains two types of cord clamps for CN20. Use the one that matches the cable diameter.

- Each connector set should be assembled according to the instructions specified by the connector manufacturer.

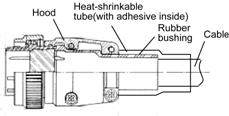

The table below shows an assembly procedure example of a connector set for CN20, 21. The actual assembly procedure should be in accordance with the instructions specified by the connector manufacturer.

Overview of Assembly Procedure Example of Connector Set for CN20, 21

| Components of connector set for CN20,21 | Assembly procedure example |

|---|---|

|

(For straight plug) |

|

ID : 6521