ID : 4657

Semiyearly Inspections

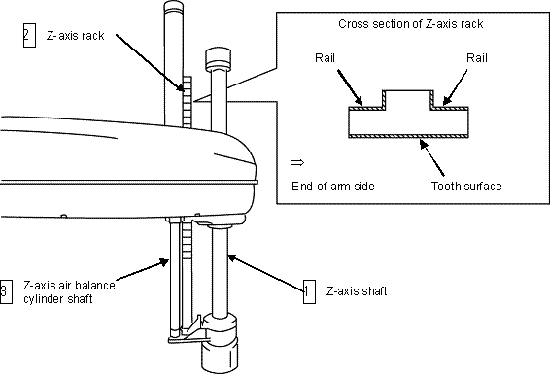

Apply the specified grease to the whole Z-axis shaft as shown below.

When moving the Z-axis shaft, be careful not to let the shaft drop/rise or your finger get caught in it.

| No. | Grease points | Grease type | Amount of grease | Remarks |

|---|---|---|---|---|

| 1 | Z-axis shaft | EPNOC AP1 | 2 to 3 cc | Apply the grease to the whole Z-axis shaft. |

| 2 | Z-axis rack | EPNOC AP1 | 2 to 3 cc | Apply the grease to the rack and gear of the Z-axis shaft. |

| 3 | Z-axis air balance cylinder shaft | EPNOC AP1 | 2 to 3 cc | Apply the grease to the whole cylinder shaft. |

<Example of HM> |

||||

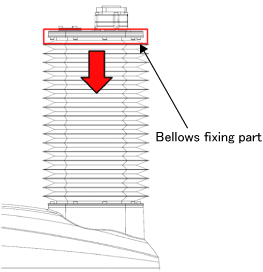

When applying grease to the dust- & splash-proof type, you need to pull down the upper bellow on the Z-axis shaft.

For the clean room type, be sure to remove the upper bellows fixing part, and then press down the bellows as shown in the figure below.

Precautions for Handling of the Grease

- Eye contact: Rinse with clean water carefully for several minutes. Remove contact lenses if present and if removal is easy, then continue rinsing. Rinse for 15 minutes at a minimum and seek medical attention.

- Skin contact: Immediately flush skin with large amounts of water. Wash contaminated clothing before reuse. If skin irritation occurs: Get medical advice/attention.

- Inhalation: Remove person fresh air and keep comfortable for breathing. Cover the body with blankets to keep warm and quiet. If you feel unwell, seek medical advice.

- Ingestion: Do not induce vomiting. Drink [one glass] [two glasses] of water. Call a physician [or poison control center] immediately.

ID : 4657