ID : 4721

Components 1

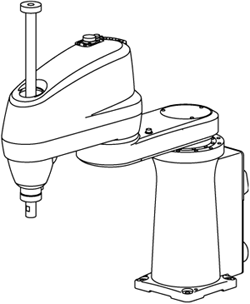

Robot Unit

Robot units

Motor & Encoder Cable (option)

| Standard type |  |

|---|---|

| Splash-proof type |  |

| Splash-proof type (UL) |  |

Cable that connects the robot unit to the robot controller, consisting of a motor cable and an encoder cable.

When placing an order for a robot system, select a motor & encoder cable from the list given below.

For partnumber and outer dimensions, please refer to "Options for Robot Unit".

| Type | Item / Specifications | ||

|---|---|---|---|

| Models except UL-Listed ones |

Motor and encoder cable standard type |

Straight | 2 m |

| 4 m | |||

| 6 m | |||

| 12 m | |||

| 20 m | |||

| Angle | 2 m | ||

| 4 m | |||

| 6 m | |||

| 12 m | |||

| 20 m | |||

Motor and encoder cable splash-proof type |

Straight | 2 m | |

| 4 m | |||

| 6 m | |||

| 12 m | |||

| 20 m | |||

| Angle | 2 m | ||

| 4 m | |||

| 6 m | |||

| 12 m | |||

| 20 m | |||

| UL-Listed models (for RC7M) |

Motor and encoder cable splash-proof type (RC7M) |

Straight | 2 m |

| 4 m | |||

| 6 m | |||

| 12 m | |||

| Angle | 2 m | ||

| 4 m | |||

| 6 m | |||

| 12 m | |||

- The bending radius (internal) of a motor & encoder cable should be at least 33.8 mm when the cable is stationary, and at least 225 mm when it is movable. Excessively bending will result in broken lead wires.

- If the length of the motor and encoder cable is 20 m, the leakage current of power supply exceeds 3.5 mA. To reduce the touch current on the controller surface to 3.5 mA or less, take any measures, for example, connecting additional protective earthing conductor which cross section is 2.5mmˆ2 or larger to the controller.

Connector to Join the Cable to the Robot Unit

| Standard type | Splash-proof type / UL-Listed model |

|---|---|

|

This is IP67 rated when it is connected Do not touch the O-ring on the connection face. |

Connector to Join the Cable to the Robot Controller

| Model except UL-Listed ones | UL-Listed model |

|---|---|

|

|

This is not IP67 rated.

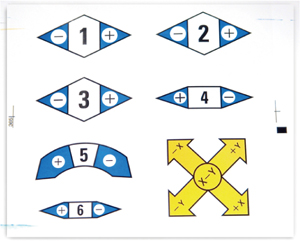

Sheet of Direction Indicator Labels

Labels that indicate the motion directions of individual axes.

After installation, attach the direction indicator labels in a position on the robot unit that can be easily seen.

Connector Set for Hand Control Signals

Connector set for CN20, CN21. The applicable type is depend on the robot type.

For details, refer to "Air piping and Signal wiring."

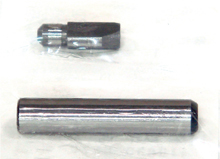

Positioning Pin (Positioning pin with internal thread & diamond locating pin)

This is the locating pin to determine the robot installation position.

ID : 4721