ID : 5620

Mount Example

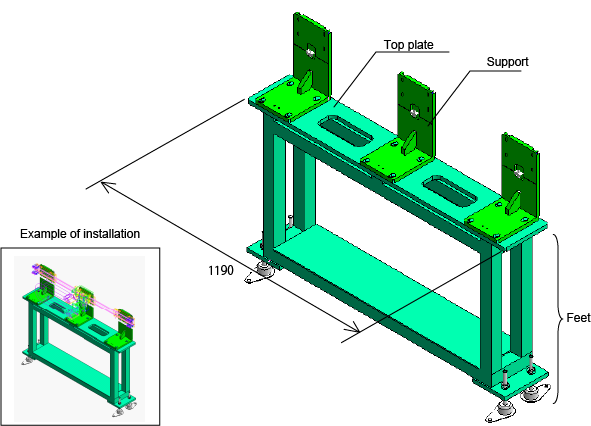

The following shows a mount example.

The height of the mounting surface is adjustable. Adjust it so that the mounting surface can keep a flatness of 0.1/500 mm.

|

The following shows the reference drawing of a mount with a 1200 mm stroke.

Reference drawing of mount (1200 mm stroke) (PDF:555KB)

The following parts are used in the reference drawing shown above.

| Item | Model | Q'ty | Manufacturer |

|---|---|---|---|

| Adjustment pad | FJKN16-130 | 4 | Misumi Corporation |

| Square nut | FK2T16-A75-P59 | 6 | Misumi Corporation |

| Block for adjustment screw | TSE6-8 | 3 | Misumi Corporation |

| Positioning bolt | STBCM6-30 | 3 | Misumi Corporation |

| Hexagon socket head bolt | TA-B2-4X16 | 6 | Meinan Co., Ltd. |

| Hexagon socket head bolt | TA-B2-6X22 | 12 | Meinan Co., Ltd. |

| Hexagon socket head bolt | TA-B2-8X22 | 12 | Meinan Co., Ltd. |

| Hexagon socket head bolt | TA-B2-10X20 | 6 | Meinan Co., Ltd. |

| Slotted hole washer | WS-S-6 | 12 | Meinan Co., Ltd. |

| Slotted hole washer | WS-S-8 | 12 | Meinan Co., Ltd. |

Positioning of the Supports

To fasten the rail unit to the supports, each support must be adjusted to the position on the rail unit which the support can be secured beforehand. The position to secure supports on the rail differs according to the length of the rail.

You need to tap as many holes on the support as required when fixing a rail unit to it. For details, refer to "Positions of Rail Unit Fixing Bolts (PDF:43KB)".

- When the robot operates at high speed, the robot mount undergoes large reaction forces. The mount must be rigid enough so that it will not vibrate or be displaced due to reaction forces. It is also advisable to mechanically join the robot mount with heavy equipment.

- Some mounts may produce a resonance sound (howling) when the robot is in motion. If this sound is loud, increase the rigidity of the mount or adjust the robot speed.

ID : 5620