ID : 1424

Example of Using System I/O Signals

This section illustrates an example of starting and stopping the robot using system I/O signals.

Equipment setup example

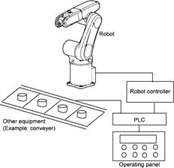

This example shown below assumes an equipment setup which allows you to run the robot by operating an external equipment’s operation panel connected via the PLC to the robot controller. It is assumed that the operating panel has a display, lamps and switches listed on the next table.

Example of Equipment Setup Using a Robot

|

Function Example of External Equipment Operating Panel

| Classification | Part | Application |

|---|---|---|

| Display | Display | Displays messages, such as ROBOT PREPARATION OK. |

|

Lamp |

Automatic operation indicator |

|

| Robot external running OK indicator |

|

|

| Operation OK indicator |

|

|

| Robot home position indicator |

|

|

|

Switch |

Robot preparation button | Starts the preparation of the robot. |

| Automatic start button | Starts the operation of the equipment. | |

| Cycle stop button | Stops the equipment after a cycle of operations is completed. | |

| Operation/ Adjustment selector switch |

|

Actual equipment requires emergency stop, interlock and other functions; however, described here are the necessary functions.

ID : 1424

- Related Information

- Outline of procedure

- Start and stop procedure, and system I/O signals