ID : 4495

Control Log

A record of the robot's control, including movement of axes, current values, load ratios, etc.

This is useful in the following cases.

- Checking robot behavior within a specified range.

- Checking the age deterioration of the robot.

- Approximating the minimal load on the motor by predicting load ratios.

The control log recording time can be set by specifying the recording interval and number of records.

Recording can be made manually from the teach pendant or WINCAPSIII or through program operations.

The recording timing of the program is controlled using "SysLog.Ctrl.Start", "SysLog.Ctrl.Stop" and "SysLog.Ctrl.Clear" commands. For details, refer to "Logging" of FUNCTION GUIDE.

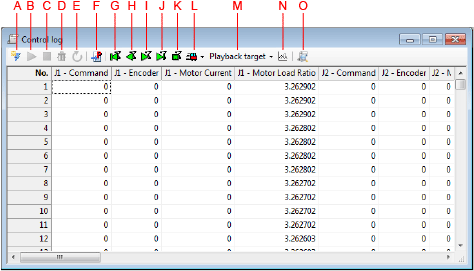

Grid Display

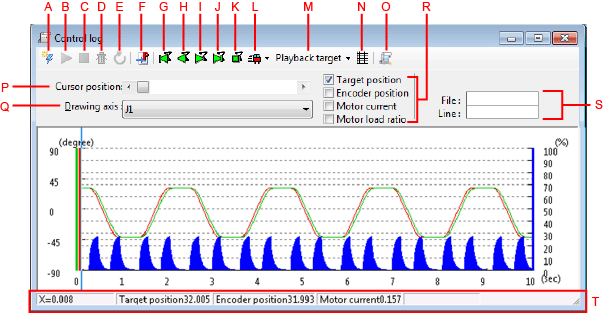

Graph Display

Description of the Drop-down Menu

A: Receive Button

This receives control log data from the robot controller and displays it.

B: Start Control Log Button

This starts or resumes the control log. SysLog.Ctrl.Start is executed.

C: Stop Control Log Button

This stops the control log. SysLog.Ctrl.Stop is executed.

D: Clear Control Log Button

This button clears the currently retained control log. SysLog.Ctrl.Clear is executed.

E: Update Control Log Button

This button updates the control log data simulating.

F: Jump to Source Code Button

This displays the source code for the selected log program.

G: Reverse Step in Button

This reproduction button plays back the control log, producing step-by-step robot motion in the reverse direction in the Arm 3D view.

H: Reverse Playback Button

This reproduction button plays back the control log, producing robot motion in the reverse direction in the Arm 3D view.

I: Playback Motion Button

This reproduction button plays back the control log, producing robot motion in the Arm 3D view.

J: Step in Button

This reproduction button plays back the control log, producing step-by-step robot motion in the Arm 3D view.

K: Stop Control Button

This button stops reproduction using the control log.

L: Speed Control

This controls the robot operating reproduction speed in the Arm 3D view subject to testing priority. There are two choices.

- Priority to collision detection

Robot movement is reproduced for each log data line. For collision detection you can prioritize collision determination with slowed down reproduction. - Priority to actual running times

Reproduction of operation matches the actual speed. (The collision may not be accurately determined.)

M: Playback target Button

Select the data for the playback of control log.

N: Graph Display / Grid Display Button

Switches the display style (graph/grid) for the control log data.

O: Control Log Analysis

The analysis results (predictive load ratio, maximum load ratio) are displayed in the output window.

- Predictive load ratio

Displays the predictive load ratio for a series of operations in the log range of processes. If the predictive load ratio exceeds 80%, an overload error is likely to occur. - Maximum load ratio

Displays the maximum load ratio in the log. At over 100% an overload error will occur.

P: Cursor Position

Moves the position of the cursor in the graph.

Q: Drawing Axis

Selects a data axis displayed in the graph.

R: Select Display Item

The checked items are displayed in the graph.

S: File / Line

Displays the File name and source code line at the cursor position.

T: Status

Displays the cursor position coordinates and the cursor position values of log data displayed in the graph.

The following items are recorded for the log data.

- Axis command values

Axis angles commanded by the controller in the specified recording interval - Axis encoder value

Current axis angle values (actual values) - Axis current values

Current values in the motors of the axes (compared with the rated value)In RC7M, the displayed value was a value compared with the overcurrent error detection level.

- Axis load ratios

Load ratios in the axes

ID : 4495