ID : 2867

Setting Procedure of the Circular Tracking

Outline

This section describes the outline of how to set up the circular tracking.

(1) Selecting a Hardware

In this step, execute various settings of hardware.

- Selecting the conveyors and devices

- Setting of the encoder joint number

- I/O setting

(2) Hardware Connection Confirmation

In this step, execute Joint and I/O setting confirmation.

(3) Calibration

Calibration measures the exact positional relationship between the turntable, sensor (vision sensor), and robot.

Detailed Procedure

Detailed setting procedures are different for sensor tracking and for vision tracking.

For details about the sensor tracking, refer to "Setup of the Sensor Tracking".

For details about the vision tracking, refer to "Setup of the Vision Tracking System".

Adding the Circular Tracking Function to the Existing Robot Controller

When adding the circular tracking function to the existing robot controller, the license of the circular tracking function and the encoder hub are necessary.

Please contact your DENSO representative for more details.

When adding the circular tracking function to the robot controller, customers need to change the project data of the robot controller to the project for extended-joint.

In that case, please perform the procedure below.

Procedure to Change to the Project Data for Extended-joint

With WINCAPSIII, after getting data from the robot controller and changing to the project for extended-joint, send data to the robot controller.

1

Use WINCAPSIII.

| Operation path:[File] - [New Project] |

Select "Get information from the controller for creating a new project.", create data.

For details, refer to "Creating a New Project".

2

| Operation path:[Project] - [Property] |

Change to "Use" by [Change] button of "Robot info." tab.

For details, refer to "Robot" of "Robot info." tab.

3

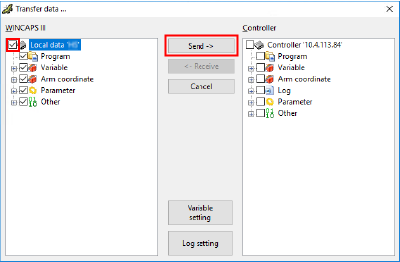

| Operation path:[Connect] - [Transfer data] |

Select "Local data" of WINCAPSIII and click [Send].

When sending is complete, please restart the controller.

ID : 2867

- Related Information

- Setup of the Sensor Tracking

- Setup of the Vision Tracking System