ID : 5631

Changing the S Axis Mechanical End

The restriction of the motion range of the S axis is achieved by changing the joint position of the drive timing belt.

If the mechanical end of the S axis needs to be changed, please contact our sales representatives. The warranty does not cover damage or injury resulting from repairs undertaken by other than our service representatives.

Changing the Joint Position of the Drive Timing Belt

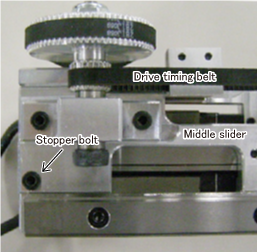

There are two types of timing belts. This section shows how to adjust the joint position of the drive timing belt.

1

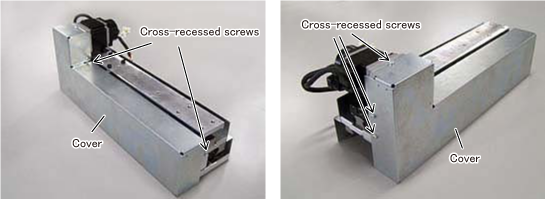

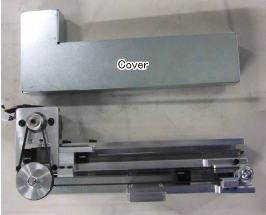

Remove the five cross-recessed screws on the body of the S axis.

2

Take out the cover of the S axis.

3

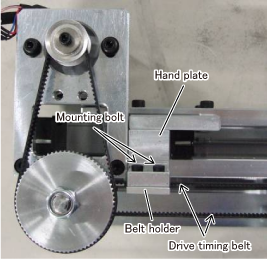

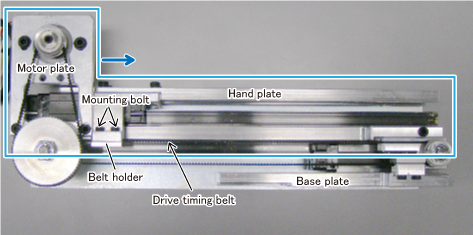

Loosen the two mounting bolts on the hand plate so that the joint position of the drive timing belt and the belt holder can be adjusted.

4

Slide the motor plate and hand plate together against the fixed base plate to the blue arrow direction (see image below). Find the joint position of the drive timing belt so that the motion range of the unit will be suitable for the use, and then tighten the unit with the two mounting bolts.

| Tightening torque | 2.0±0.2 N・m |

|---|

5

Attach the stopper bolt on the lateral side of the base plate of the middle slider.

| Stopper bolt | M4×8 1 piece |

|---|---|

| Tightening torque | 3.9±0.8 N・m |

6

Attach the cover which was taken out in STEP1 and STEP2, then fasten it with the five cross-recessed screws.

| Tightening torque | 0.59±0.06 N・m |

|---|

This is the end of the setting change procedure.

ID : 5631