ID : 5635

Grease Lubrication

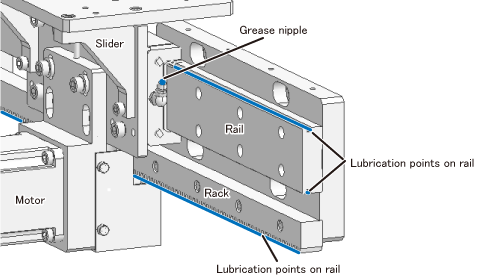

Lubricate the specified greases to the slideways of the robot with reference to the following table.

Lubrication Points

| Lubrication points | Lubrication type | Lubricant amount |

|---|---|---|

| Rack | Epinoc AP1 | 1.0 to 1.3 g/m |

| Rail | Epinoc AP1 | 0.5 to 1.0 g/m |

| Two grease nipples on slider | Epinoc AP1 | 2 to 3 cc |

Grease Feeding Method

- Grease feeding for rack and rail

Apply grease evenly on the entire lubrication area.

- Grease feeding for slider

Using a grease gun, apply grease to the two grease nipples on the sides of the slider.

Improper lubrication points, amount of grease, or lubrication procedure may cause oil drops from the specified points.

Checking for Oil Drops

Check that there are no oil drops from the lubrication points. Improper environment, amount of grease, or lubrication procedure may cause oil drops.

ID : 5635