ID : 3716

Signals for Safety Operation

A COBOTTA equips two signals for safety operation: a signal that users can stop COBOTTA motion in case a COBOTTA performs unexpected motion (hereafter, "emergency stop input signal"); and a signal to stop a COBOTTA motion if a worker enters a predetermined area (hereafter, "protective stop input signal").

This section explains how to use signals for safety operation (safety signals).

Note that a COBOTTA cannot move unless safety signals are connected properly. For about how to connect signal lines, please refer to "Connection Circuit for Safety Signals".

Emergency Stop Input Signals

There are two types of emergency stop input signals.

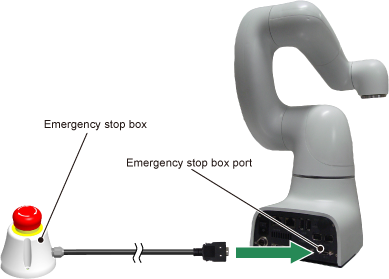

One is only for COBOTTA itself. For this signal, use an emergency stop box, which is shipped with a COBOTTA at purchase. Am emergency stop box connects to the emergency stop box port on the COBOTTA as the following image shows.

Pressing a button on the emergency stop box while a COBOTTA is running, the COBOTTA will stop the motion.

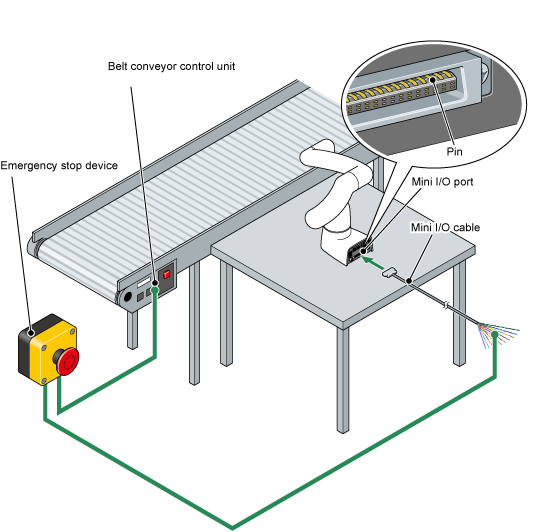

The other signal is for machinery including a COBOTTA. For this signal, use "external emergency stop input signals", which are allocated to the Mini I/O port on COBOTTA (A Mini I/O port has several pins. Variety of signals are allocated to these pins).

The following shows a system example consisting of a COBOTTA and a belt conveyor. Assuming that the machinery could be in danger unless both COBOTTA and belt conveyor are stopped during operation. As a countermeasure for that, connect the COBOTTA and belt conveyor so that one emergency stop device can stop both operation. In this case, connect the external emergency stop input signals to the COBOTTA.

For details about how to connect external emergency stop input signals, please refer to "Connection Circuit for Safety Signals".

Protective Stop Input Signals

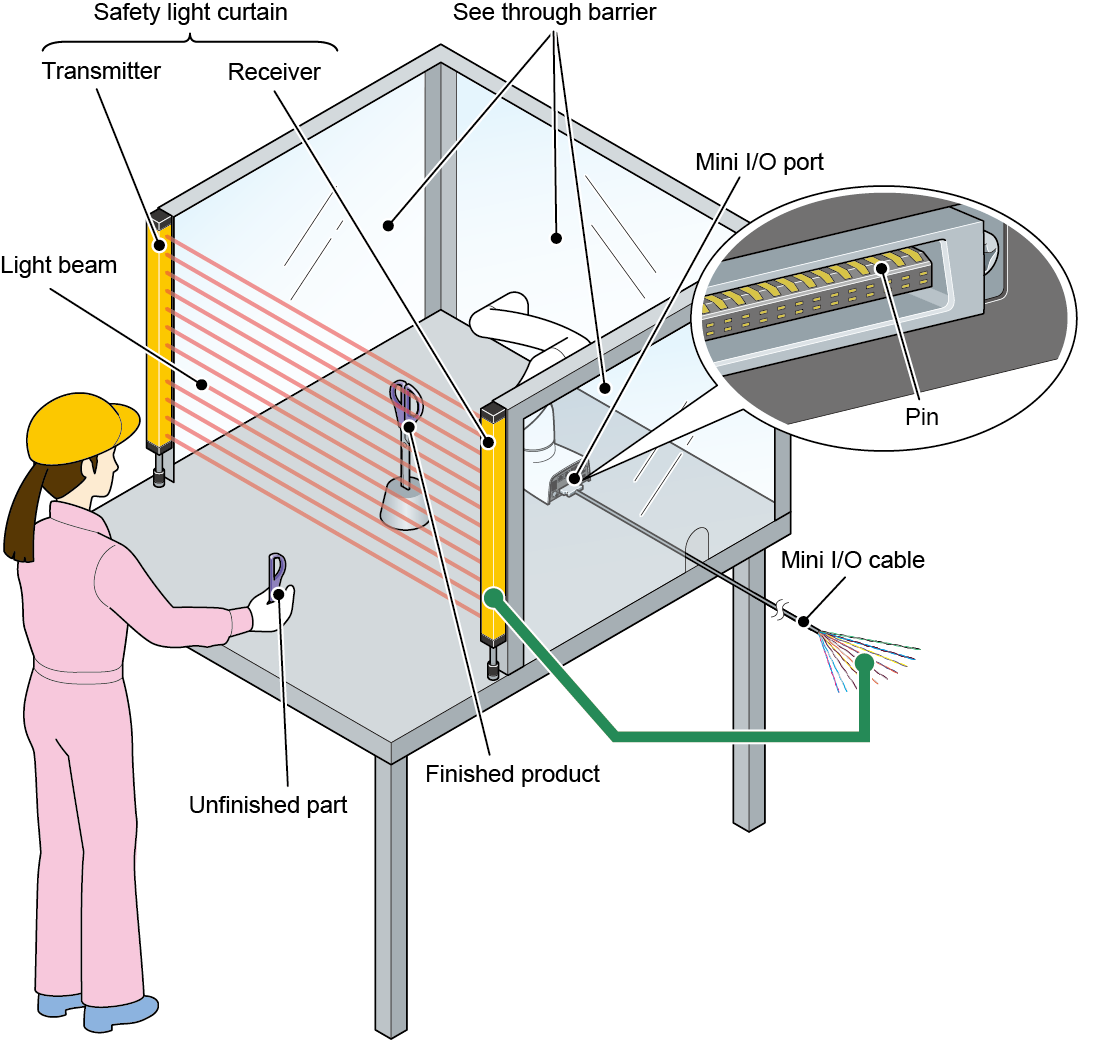

A COBOTTA is designed to stop its operation in case it collides with any object or personnel with a contact force more than the predetermined threshold. However, depending on the way of COBOTTA operation, a COBOTTA could be a danger. (E.g.; carrying a sharp object by COBOTTA). For such operation, as a result of safety inspection (this process is called a "risk assessment", conducted by customers), any preventive measures for personnel entry in the COBOTTA motion area may be required. This is the example of a such robot system.

As the following image, if a production line includes a process that operators replace a finished part (a workpiece) on a workbench with an unfinished part, they have to enter their hands into the cage. In this case, using a safety light curtain is practical. A safety light curtain is a personnel presence detection device that consists of a transmitter and a receiver. In the normal state, the transmitter projects an array of parallel light beams to the receiver. When a human body (for example, operator's hands) breaks one or more of the beams, the receiver detects the stop of beams, as a result, it determines that a personnel enter the safeguarded area.

A safety light curtain outputs the personnel's entry state to the output signal lines. By utilizing this signals, a system stops COBOTTA operation. In this case, protective stop input signals, which are allocated to the Mini I/O port on COBOTTA, are used. (A Mini I/O port has several pins. Variety of signals are allocated to these pins).

Once a signal of personnel's entry is informed to the protective stop input signals, a COBOTTA stops its operation. However, in this step, the COBOTTA's motion process (a robot program) is suspended-state. When an operator restart the COBOTTA's robot program after replacing the work piece, the program resumes from where it was suspended.

On the other hand, if a COBOTTA is forcibly stopped by an emergency stop input signal, the robot program will be reset. In this case, when you restart the robot program after the stop, the COBOTTA runs the robot program from the start line.

When you need to stop a COBOTTA motion temporarily, but need to resume the robot program from where it is suspended, using a protective stop input signal is one of the practical solution.

For details about how to connect protective stop input signals, please refer to "Connection Circuit for Safety Signals".

ID : 3716