ID : 2888

Parameter Setting

This section describes the parameter setting procedure.

Parameter Setting Procedure

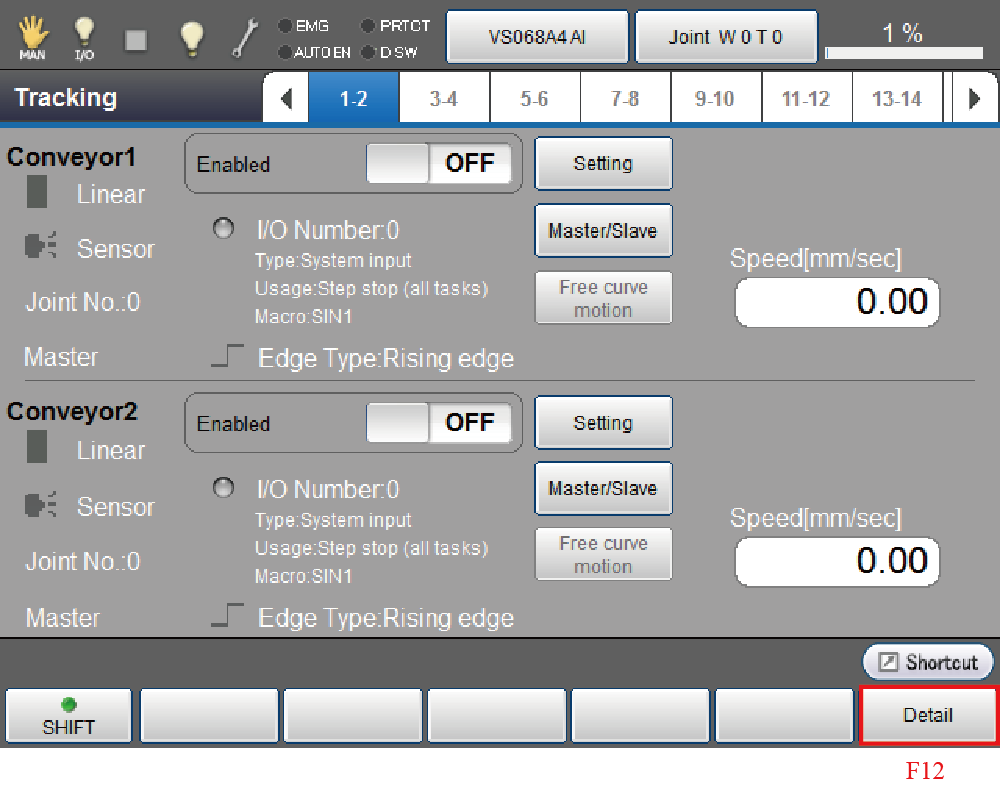

1 Displaying Detail Setting Window

Press [F12 Detail] on the "Tracking" window.

Conveyor Tracking window is displayed.

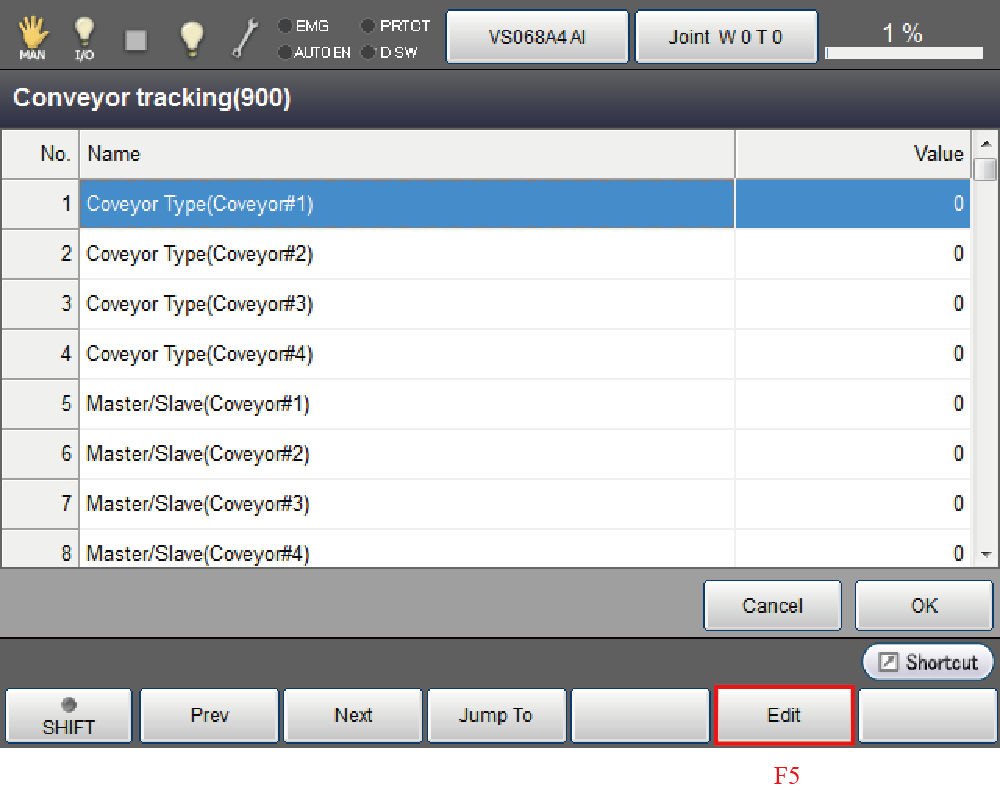

2 Selecting Setting Item

Select an item to set, then press [F5 Edit].

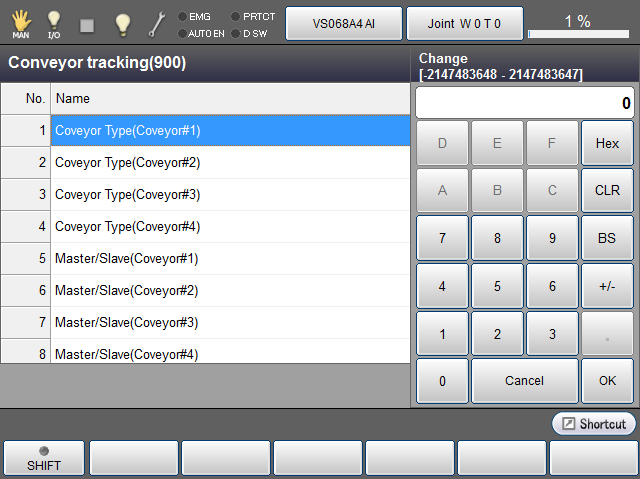

3 Changing Setting Value

Input parameters with the numeric keypad, then press [OK].

Parameter List

The parameters described in the table below are not configured automatically in the Detail window.

| Parameter name | Description |

|---|---|

| Tracking Start Range | Refer to the corresponding item of "Terminology and Definitions". Enter a negative value to offset to the upstream direction. |

| Minimum Interval between workpieces (Vision Sensor) | This is a threshold value which prevents duplicate data of the work that already exits in the tracking buffer from being registered by TrackSetVision command. |

| Low pass filter TC for conveyor pulse | This controls a sudden fluctuation of value by filtering the input value form the encoder. Setting a value too high lowers the responsiveness to the fluctuation of input value. |

| speed proportional gain | Use this parameter when catch up accuracy of robot deteriorates when the speed of turntable is increased. When the robot cannot catch up the workpiece, set this value higher than 1. When the robot overpasses the workpiece, set this value lower than 1. |

| Stationary deviation compensation | Use this parameter when the robot catches up the workpiece always with a certain amount of shift. Specify the value with a positive value [mm] when the robot cannot catch up the workpiece. Specify the value with a negative value [mm] when the robot overpasses the workpiece. |

ID : 2888