ID : 7330

Tool Coordinates

This section describes the Tool coordinate system in the following subsections.

- Concept of Tool Coordinate System

- Tool Coordinate System When Using the Electric Gripper for COBOTTA

Concept of Tool Coordinate System

Based on a mechanical interface coordinates system, you may define tool coordinates system, which is Cartesian coordinates, by offsetting the origin of the mechanical interface coordinates system to a different point, along with the size and direction of a tool, and then rotating the origin around the Z-, Y-, and X-axis of the mechanical interface coordinates system.

The point being offset will be the origin of tool coordinates system. This point is generally called TCP (Tool Center Point).

To set the tool coordinates system is called “Tool definition”. Tool definition defines the distance and rotation angle of the offset.

You can define up to 63 tool coordinates (TOOL1 to TOOL63). TOOL0 is defined by system for mechanical interface coordinates.

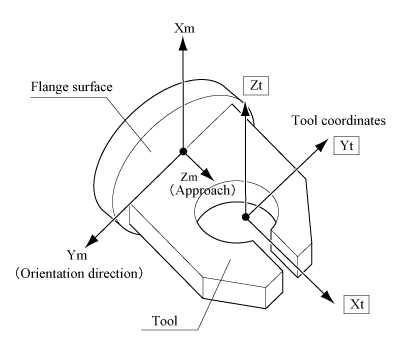

The X, Y, and Z axes in tool coordinates are expressed by Xt, Yt, and Zt, respectively, as shown below.

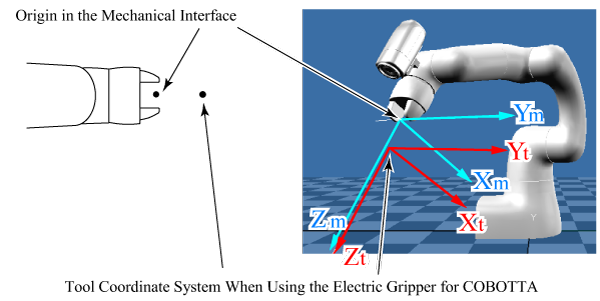

Tool Coordinate System When Using the Electric Gripper for COBOTTA

If the electric gripper for COBOTTA is installed, the origin of the mechanical interface coordinate is determined as a point which locates at the center of two fingers, existing on a plane surface across two fingers' end.

Therefore, the origin of the Tool coordinate system is defined by offsetting the origin of the mechanical interface coordinate (the center position of two fingers existing on the plane surface across two fingers' end) and by rotating it around the X-, Y- and Z-axis.

ID : 7330