ID : 402

Pallet.CalcPos

Function

Specify the pallet conditions, stack count and the target position number to retrieve the desired position.

Syntax

Pallet.CalcPos(P1_P3 divisions,P1_P2 divisions,Height of one stack,pallet 4-corner position P1,pallet 4-corner position P2,pallet 4-corner position P3,pallet 4-corner position P4,pallet target position number[, Stack count][, Robot Number])

Guaranteed Entry

- P1_P3 divisions

- Specify the number of divisions on the P1-P3 direction (N) by integer type data.

- P1_P2 divisions

- Specify the number of divisions on the P1-P2 direction (M) by integer type data.

- Height of one stack

- Specify the height of one stack by single precision real number type data. The position of the height of pallet is calculated by [Height of one stack]*([Stack count]-1). If pallets are piled up successively, enter a positive value. If pallets successively diminish in number, enter a negative value.

When you use the [Stack count] with 1 always, this value is not available. Enter 0. - Pallet 4-corner position P1

- Specify the first position in the four corners by position type data.

- Pallet 4-corner position P2

- Specify the second position in the four corners by position type data.

- Pallet 4-corner position P3

- Specify the third position in the four corners by position type data.

- Pallet 4-corner position P4

- Specify the fourth position in the four corners by position type data.

- Pallet target position number

- Specify the target position number that is counted from the first position of the stack by integer type data.

- Stack count

- Specify the stack count from the first stack by integer type data.

This should be "1" if this is omitted. - Robot Number

- This option is available in Ver.1.9.* or higher.

When the cooperative control function is used, specify the robot number range by integer type data. Available range is from 0 (Robot0) to 1 (Robot1). This is omittable. This should be "0" (Robot0) if it is omitted.

Return Value

Return a target position by position type data.

Description

Specify the pallet conditions, stack count and the target position number to retrieve the desired position.

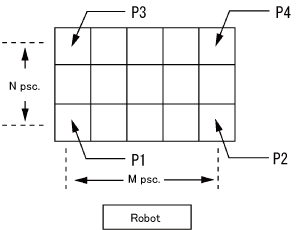

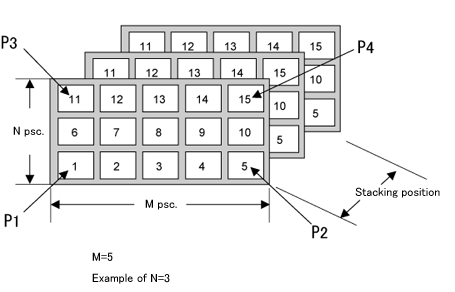

Pallet conditions to specify are; P1-P3 division (N), P1-P2 division (M), stack height, and pallet four corners (P1 to P4).

Pallet position numbers are assigned from P1 to P2 and after P2, subsequent numbers are assigned from P1 plus 1 to P3 horizontally as indicated in the figure.

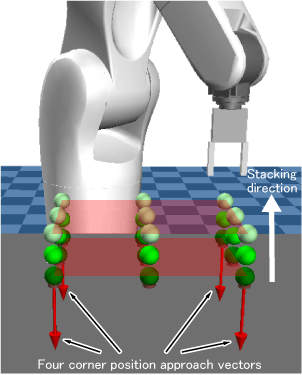

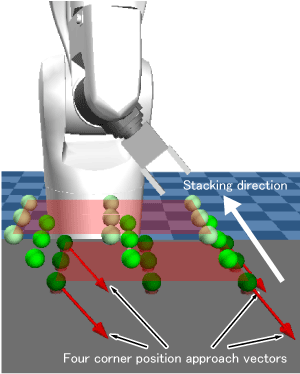

The height of one stack increases in the negative direction to the approach vectors at the four corner positions (P1-P4) of a pallet (hereinafter called “four corner position approach vectors”).

For example, when the four corner position approach vectors face in the vertically downward direction to the XY plane of the base coordinates, the height of one stack increases in the vertically upward direction from the XY plane (Example 1).

When the four corner position approach vectors face in the obliquely downward direction to the XY plane of the base coordinates, the height of one stack increases in the obliquely upward direction from the XY plane (Example 2).

Consider the height direction of stacking as well to teach the four corner positions (P1-P4) of a pallet.

In the following movies, a robot moves to positions specified by return values of Pallet.CalcPos command, and then sphere-shaped objects appear at those positions.

Example 1

Example 2

Related Terms

Attention

- If you execute this command on 4-axis robots (HM, HSR, HS, HSA1, XR robots), the process that optimizes the shoulder figure is not included, so a position that the 4th axis rotated more than one turn may be calculated in some cases. When a 4-axis robot is used, it is recommended to use Pallet.CalcPosTurning command that can acquire the position with the optimum shoulder figure.

- For 4-axis robots, the acquired results may differ between this command and Pallet.CalcPosTurning command. Please pay attention when you change this command to Pallet.CalcPosTurning command.

Example

'!TITLE "Acquiring Coordinate Position of Pallet Target Position Number"

' Acquire coordinate position designated by pallet target position number and display it on

the message output window

Sub Sample_PalletCalcPos

Dim aaa As Position

Dim bbb As Position

Dim ccc As Position

Dim ddd As Position

Dim eee As Position

Dim fff As Position

Dim ggg As Position

' Assign position indicating pallet four corner position P1 to aaa

aaa = P( 600, -100, 50, -180, 0, 180, 5 )

' Assign position indicating pallet four corner position P2 to bbb

bbb = P( 600, 100, 50, -180, 0, 180, 5 )

' Assign position indicating pallet four corner position P3 to ccc

ccc = P( 400, -100, 50, -180, 0, 180, 5 )

' Assign position indicating pallet four corner position P4 to ddd

ddd = P( 400, 100, 50, -180, 0, 180, 5 )

' Assign coordinate position of pallet target position number 1 to eee

eee = Pallet.CalcPos( 3, 5, 20, aaa, bbb, ccc, ddd, 1, 1 )

' Display coordinate position of pallet target position number 1 on the message output window

PrintDbg eee

' Assign coordinate position of pallet target position number 8 to fff

fff = Pallet.CalcPos( 3, 5, 20, aaa, bbb, ccc, ddd, 8, 1 )

' Display coordinate position of pallet target position number 8 on the message output window

PrintDbg fff

' Assign coordinate position of pallet target position number 15 to ggg

ggg = Pallet.CalcPos( 3, 5, 20, aaa, bbb, ccc, ddd, 15, 1 )

' Display coordinate position of pallet target position number 15 on the message output window

PrintDbg ggg

End SubID : 402