ID : 5360

Calibration Procedure for the Conveyor

The following shows a conveyor calibration procedures.

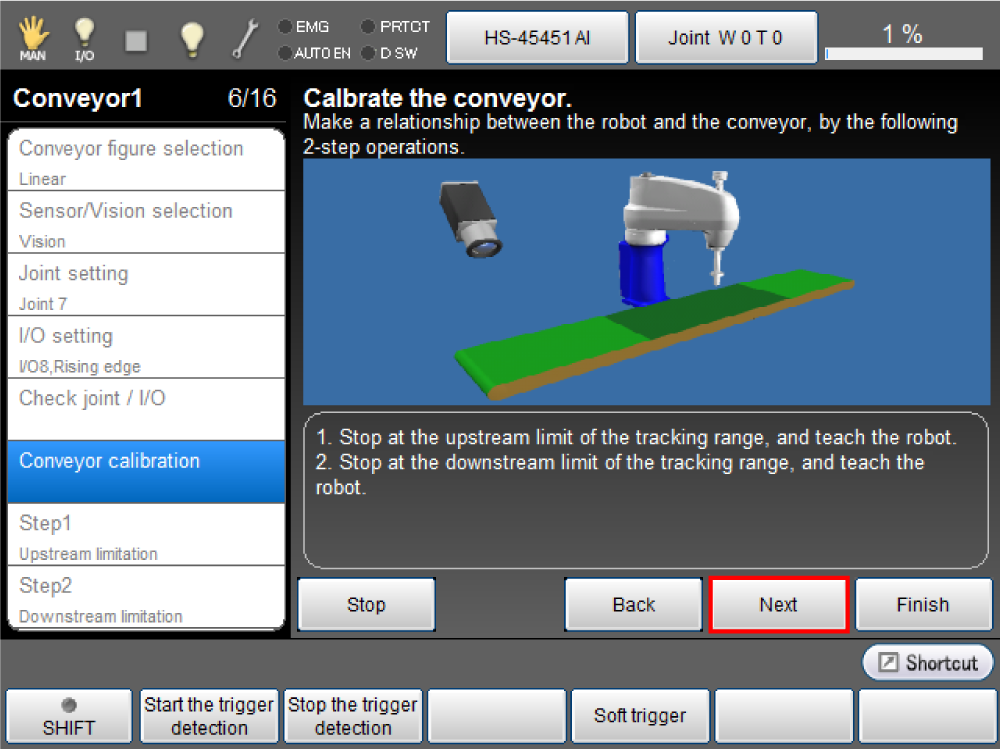

1 Confirmation of the Calibration Procedure

After confirming the calibration procedure, press [Next].

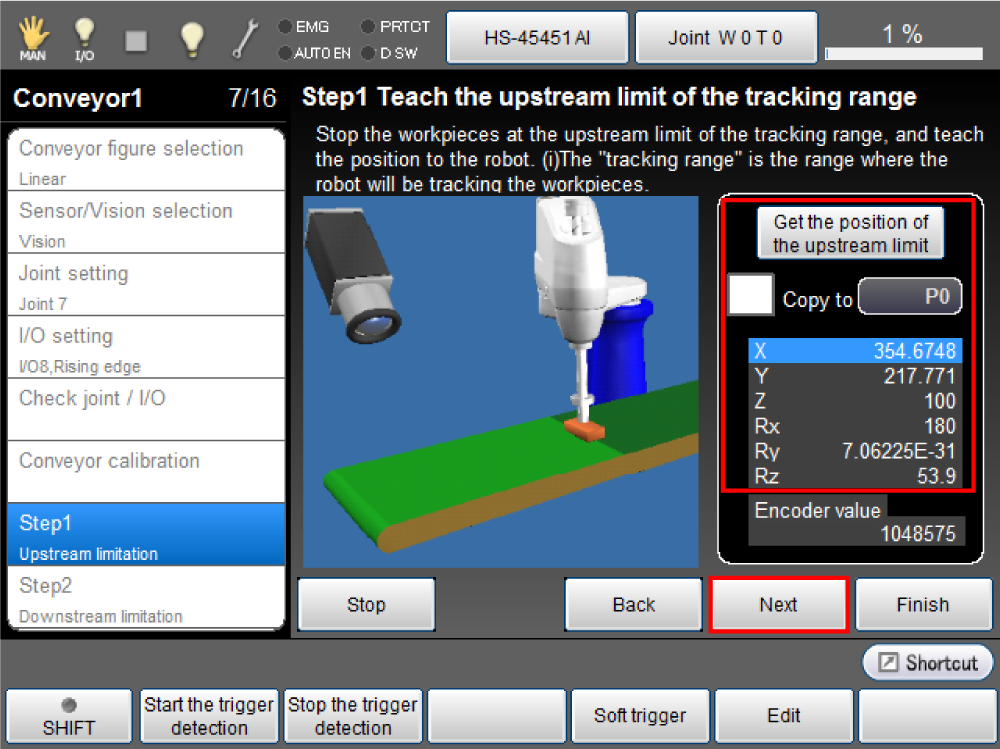

2 Executing Teaching of Upstream Limit of the Tracking Range

Stop the workpiece at the upper end limit of the tracking range.

Then move the robot to the teaching position.

Execute robot teaching and press [Get position of the upstream limit] to get the robot position.

Checks the obtained value, and press [Next] if everything is satisfactory.

- When retrying to get the robot position, a system message is displayed to confirm whether to get the position.

- The posture at the time of obtaining the upstream limit is set as the default posture of holding the work.

The obtained coordinate values can be changed. To do so, press the edit button on the bottom of the screen. Ten keys are displayed. By the ten keys, change each coordinates values.

The obtained coordinates and encoder values on both of the upstream limit and the downstream limit are used to determine the conveyor feed rate and the direction. If you change the coordinate values by the method shown above, keep in mind that the change may affect the conveyor feed rate and the direction.

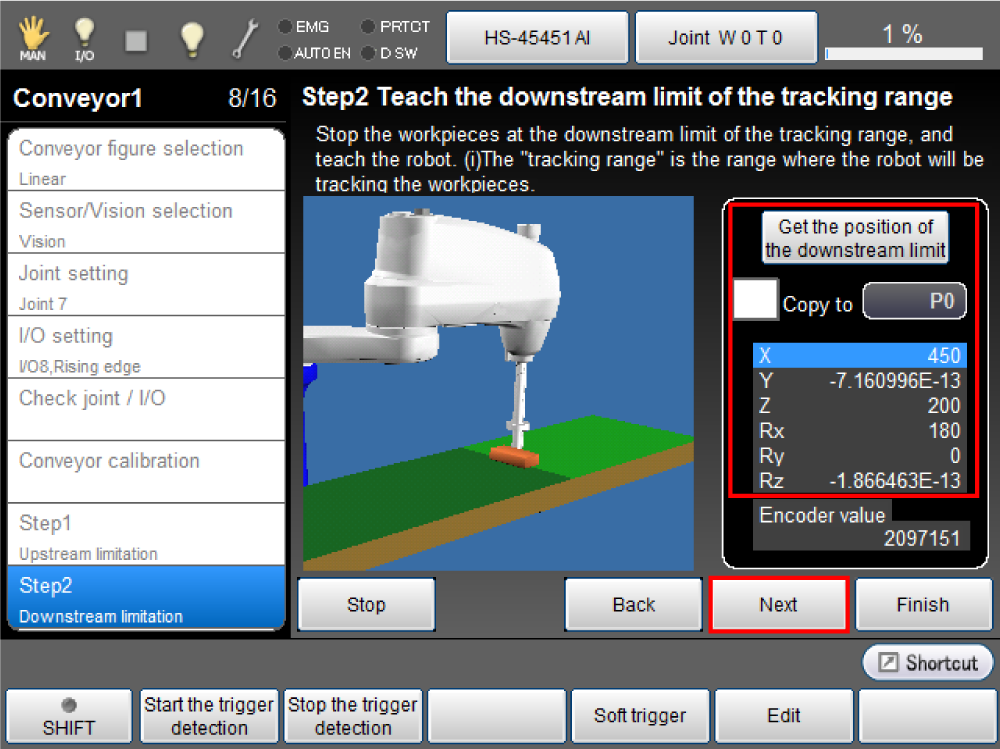

3 Executing Teaching of Downstream Limit of the Tracking Range

Stop the workpiece at the lower end limit of the tracking range.

Then move the robot to the teaching position.

Execute robot teaching and press [Get position of the downstream limit] to get the robot position.

Checks the obtained value, and press [Next] if everything is satisfactory.

The midpoint between the upstream limit position and downstream limit position is the conveyor reference position.

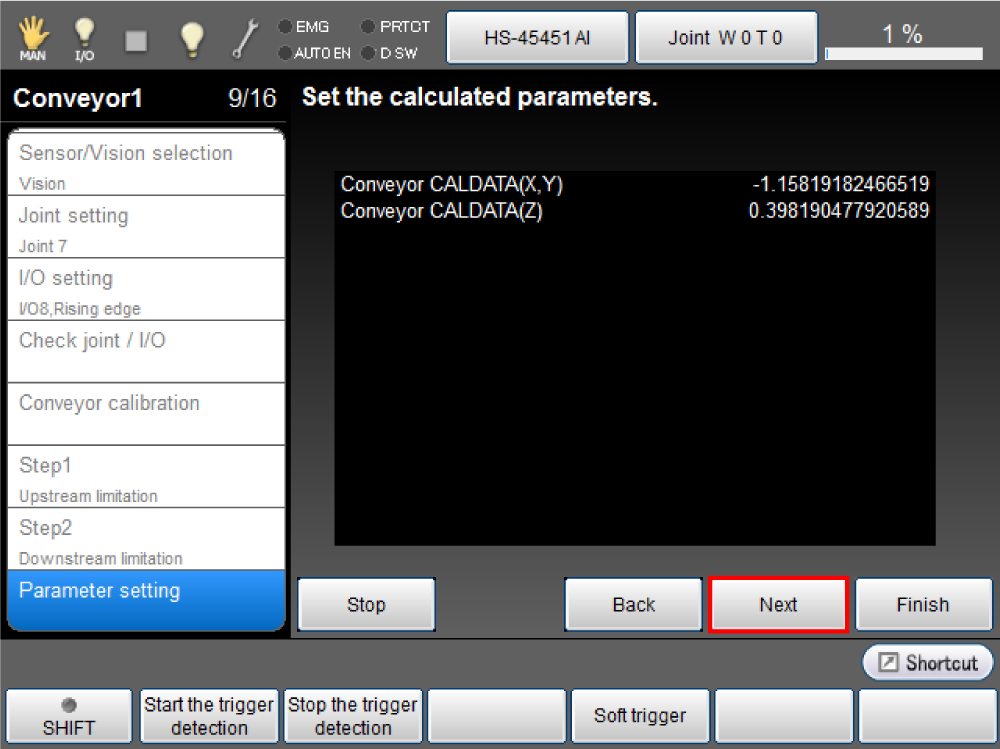

4 Confirmation of the Calibration Result

Check the calculated parameters, and press [Next] if everything is satisfactory.

This continues to "Camera calibration".

ID : 5360