ID : 5095

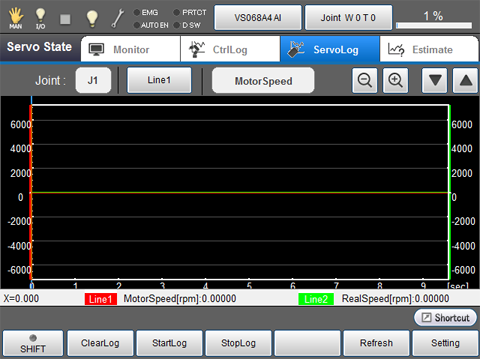

ServoLog

This function enables to record detailed information of motor control.

Conditions for servo logging

The recording interval can be set from 1 to 8 ms.

The recording time can be set from 10 to 60 s.

The following seven types of data may be recorded, two types at a time.

-

Motor Speed

Shows the control value of motor speed. (rpm)

-

Real Speed

Shows the current motor speed. (rpm)

-

Torque

Shows the substantial torque control value; that is, (Torque control value - the Torque offset value). The unit is a ratio to the rated motor torque (%).

-

Deviation

Shows the deviation between the actual motor angle and motor control angle.

Unit : Sliding axis (deg), Rotate axis (mm) -

Current

Current value of the motor.

Unit : Rated current ratio (%) -

Instruction

angle command value.

Unit : deg -

Encoder

Encoder value of the motor.

Unit: deg

Servo logging setting procedure

This section describes the servo logging setting procedure.

1

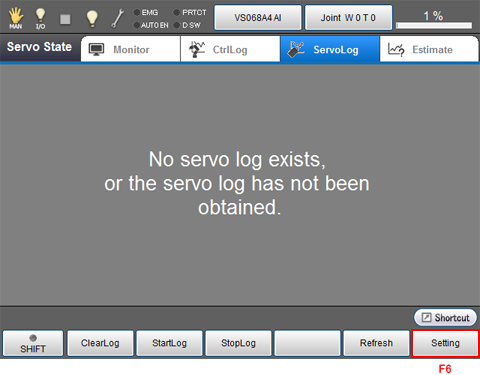

Access: Top Screen — [F2 Arm] — [F3 Servo State] — [ServoLog] - [F6 Setting]

Servo log setting window is displayed.

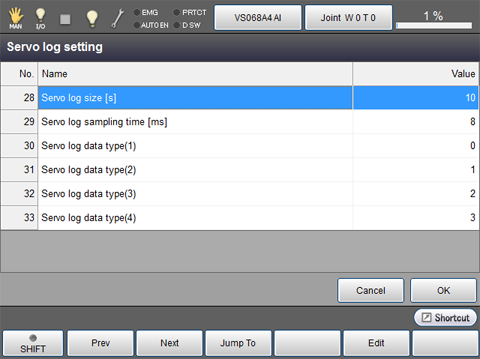

2

Change each setting of the servo logging configuration parameters, then press [OK].

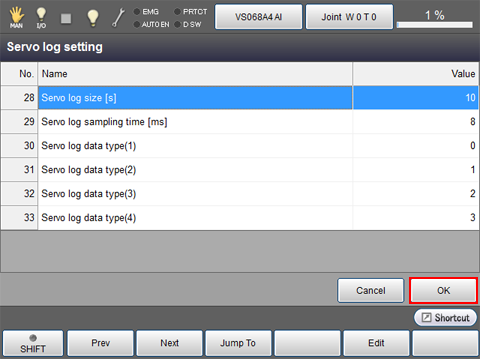

3

When all servo logging configuration parameter settings have completed, press [OK].

Servo logging configuration parameter settings are saved, then return to the Servo State window.

Starting and stopping the servo logging

There are two ways of servo logging.

- Using commands (SysLog.Servo Start, SysLog.Servo.Stop, SysLog.Servo.Clear) in the program.

- Recording the servo log manually by means of the teach pendant.

Servo logging procedure by programming

Enter the following commands to specify the timings necessary for the servo log.

- To start logging: SysLog.Servo.Start

- To end logging: SysLog.Servo.Stop

- To initialize : SysLog.Servo.Clear

For detailed information, see [SysLog.Servo.Start], [SysLog.Servo.Stop] and [SysLog.Servo.Clear].If any error occurs and the motor being logged is turned OFF during logging, then the 3.2 second after the motor stop may be recorded.

Servo logging procedure by means of the teach pendant

This chapter describes how to record servo logs by operating the teach pendant.

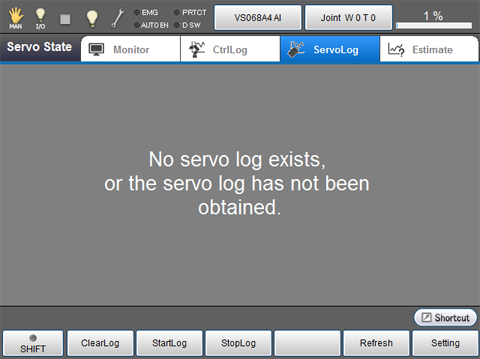

1

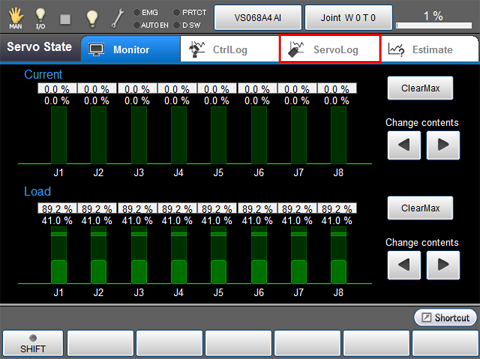

Top Screen—[F2 Arm]—[F3 Servo State]—[ServoLog tab]

[Servo State] window appears.

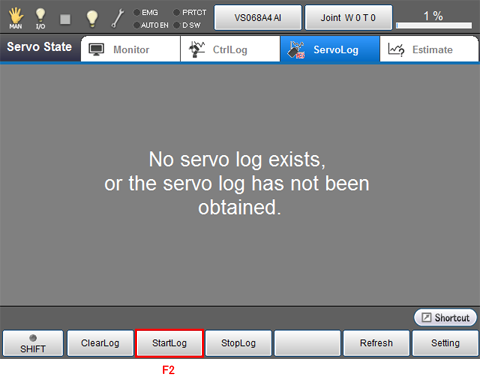

2

Press [F2 Start Log]

Servo logging is started and the "REC" icon appears on the servo log tab.

When the recording time exceeds the value of "Servo log size[s]"in the Servo log setting window, the servo logging stops automatically then "REC" icon disappears.

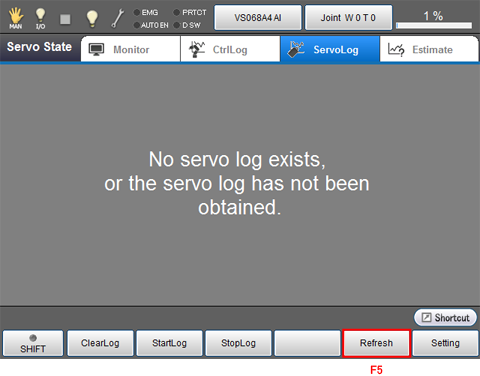

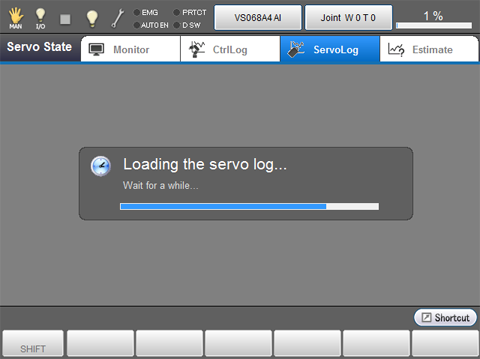

3

Press [F5 Refresh]

Recorded servo logs are read.

Recorded servo logs are displayed.

ID : 5095