ID : 3414

Programming for the Dual Arm Control Function-Used Operation

The following describes the programming information in three sections.

- Programming Examples of the Sensor Tracking

- Programming Examples of the Vision Tracking

- Other Programming Example

Programming Examples of the Sensor Tracking

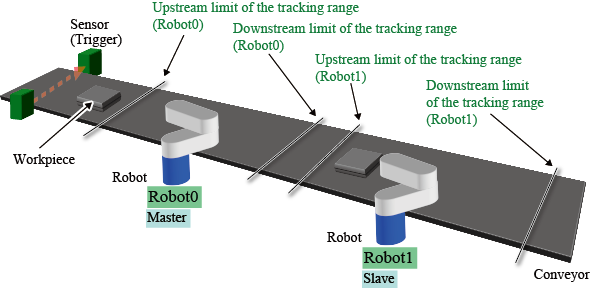

Now we will explain the program for the following system. The size of workpiece shall be less than the tracking range.

The following figure shows the overall configuration of the expected system.

(File names used in the following image are samples. You can give any names.)

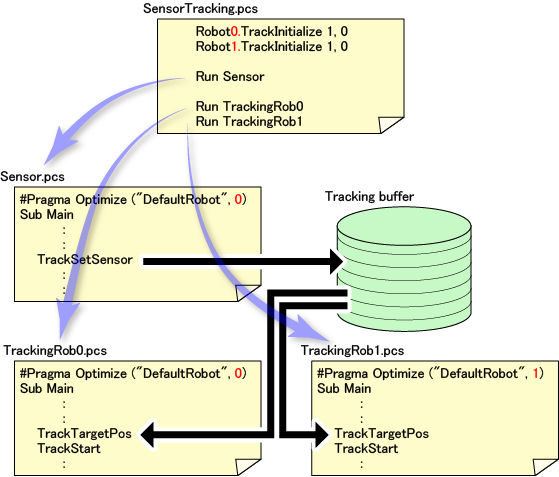

The following table contains the sample program file and description of each program.

There are two prerequisites.

- Conveyor number should be 1.

- Trigger signal from the sensor is connected to the I/O port #48 and the signal is detected at the rising edge.

|

Program name (Sample program) |

Description |

|---|---|

|

This program initializes the conveyor tracking system and executes three other programs. Initialization is done for both Robot0 and Robot1. There are two ways to specify a robot name (Robot0 / Robot1) for a command. In the sample program, "Robot0." or "Robot1." are entered in front of the initialization command "TrackInitialize". |

|

|

This program detects workpiece positions and registers the obtained data into tracking buffer. In this example, Robot0 is a master. Workpiece registration into the tracking buffer must be done for the master (in this case, Robot0). Therefore, this program is written as Robot0 program. In the sample program, the following line is added in front of the program to specify that the program is written for Robot0. |

|

|

This program reads positional data of the workpiece from the tracking buffer area, and orders Robot0 to execute tracking and picking up operation by use of obtained positional data. In the sample program, the following line is added in front of the program to specify that the program is written for Robot0. |

|

|

This program reads positional data of the workpiece from the tracking buffer area, and orders Robot1 to execute tracking and picking up operation by use of obtained positional data. In the sample program, the following line is added in front of the program to specify that the program is written for Robot1. |

For information about how to specify the robot name (Robot0 / Robot1), refer to "Data Registration to the Tracking Buffer" in "Basic Knowledge (The Concept of Master and Slave)".

Programming Examples of the Vision Tracking

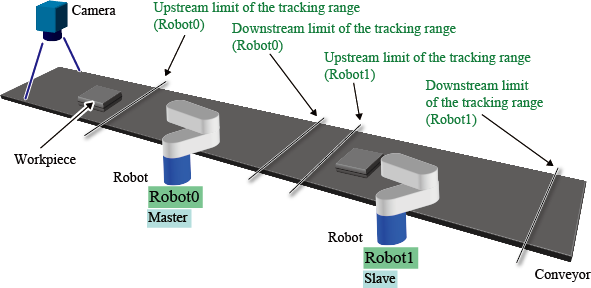

Now we will explain the program for the following system. The size of workpiece shall be less than the tracking range.

The following figure shows the overall configuration of the expected system.

(File names used in the following image are samples. You can give any names.)

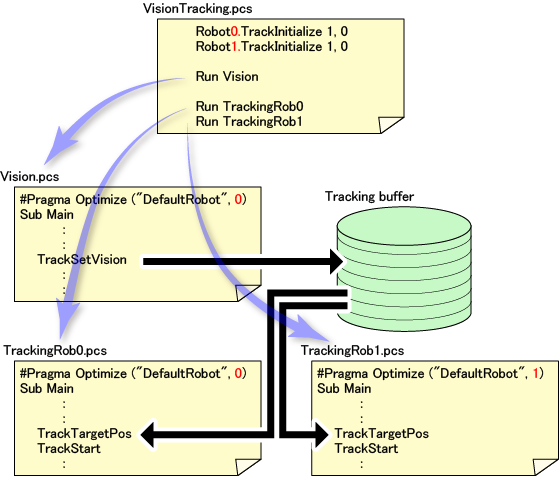

The following table contains the sample program file and description of each program.

There are two prerequisites.

- Conveyor number should be 1.

|

Program name (Sample program) |

Description |

|---|---|

|

This program initializes the conveyor tracking system and executes three other programs. Initialization is done for both Robot0 and Robot1. There are two ways to specify a robot name (Robot0 / Robot1) for a command. In the sample program, "Robot0." or "Robot1." are entered in front of the initialization command "TrackInitialize". |

|

|

This program detects workpiece positions and registers the obtained data into tracking buffer. Workpiece registration into the tracking buffer must be done for the master. In this example, Robot0 is a master. Workpiece registration into the tracking buffer must be done for the master (in this case, Robot0). Therefore, this program is written as Robot0 program. In the sample program, the following line is added in front of the program to specify that the program is written for Robot0. |

|

|

This program reads positional data of the workpiece from the tracking buffer area, and orders Robot0 to execute tracking and picking up operation by use of obtained positional data. In the sample program, the following line is added in front of the program to specify that the program is written for Robot0. |

|

|

This program reads positional data of the workpiece from the tracking buffer area, and orders Robot1 to execute tracking and picking up operation by use of obtained positional data. In the sample program, the following line is added in front of the program to specify that the program is written for Robot1. |

For information about how to specify the robot name (Robot0 / Robot1), refer to "Data Registration to the Tracking Buffer" in "Basic Knowledge (The Concept of Master and Slave)".

Other Programming Example

As programming example of conveyor tracking operation, we offer "Sample Program for a Workpiece whose Length is Over the Tracking Range" and "Programming Examples of Free Curve Interpolation during Tracking". These sample programs are created for operations with one robot. However, you can partly reuse them by specifying Robot0 and/or Robot1. Refer to other content stored in the lower layer of "Programming".

ID : 3414