ID : 2276

Equipment Protection by Area Function

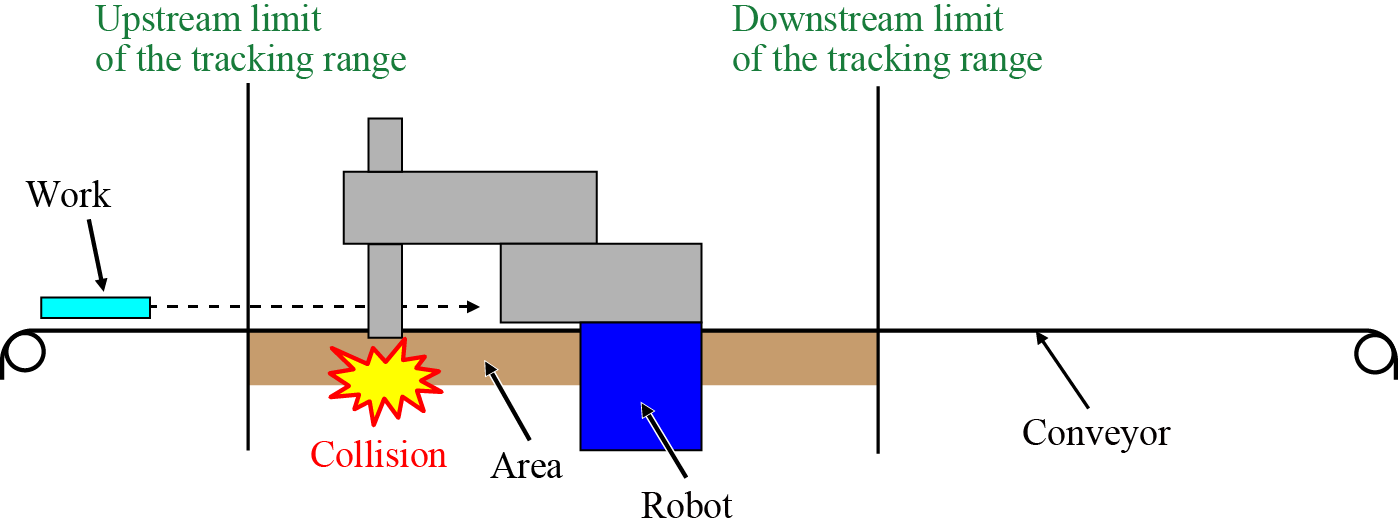

Collision between Conveyor and Robots

Robot controllers do not have any information of conveyor height; therefore, robots may collide with a conveyor during the conveyor tracking operation as the figure below shows.

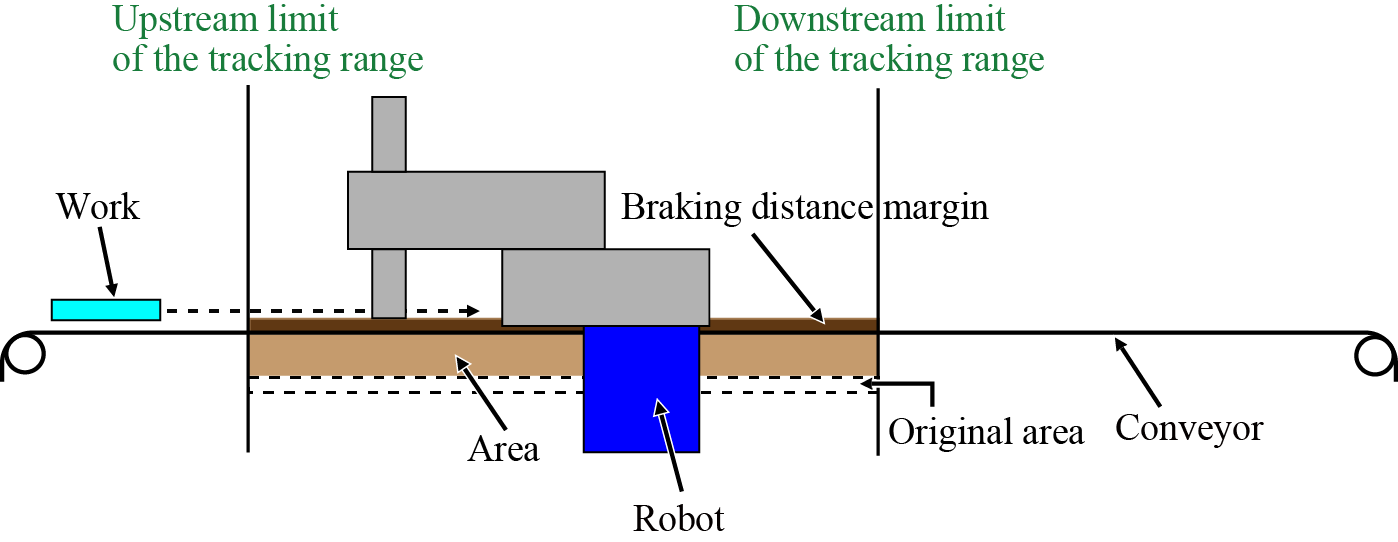

To prevent unintended contact between robots and conveyor, it is recommended to perform collision check by using Area function.

When you perform collision detection, please take enough margin for braking distance into account since robots cannot stop immediately after collision detection.

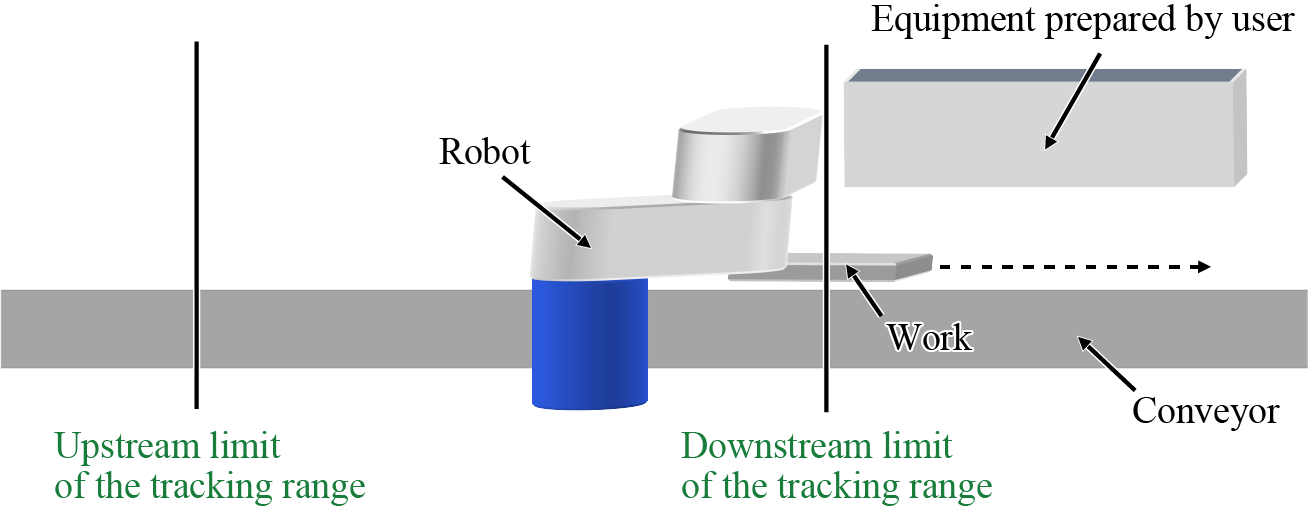

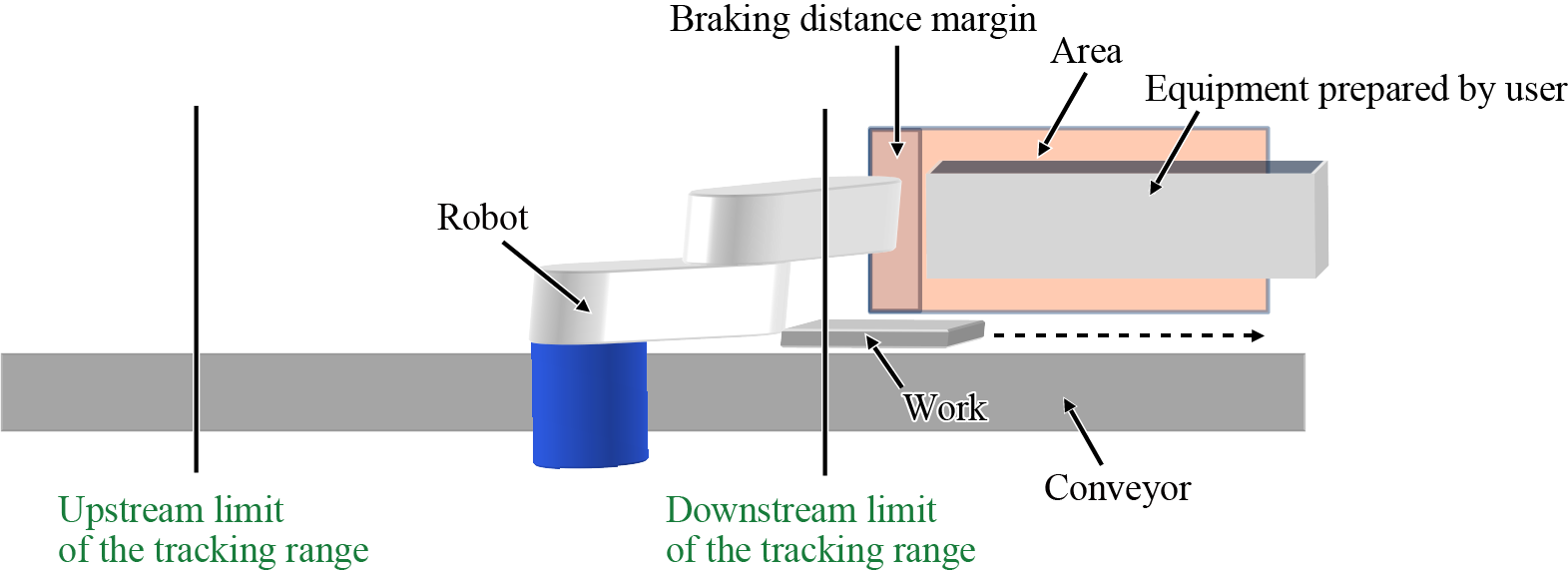

Collision between Robots and Equipments that are Placed behind the Tracking Range

In conveyor tracking system of RC8 series robot controller, Downstream limit of the tracking range is provided in order to clarify the range in which robot can follow the conveyor.

Robots may reduce the speed and stop once it passes the Downstream limit of the tracking range.

Please note that, in option setting of TrackStart command, if Error setting is enabled, a robot moves across the Downstream limit of the tracking range.

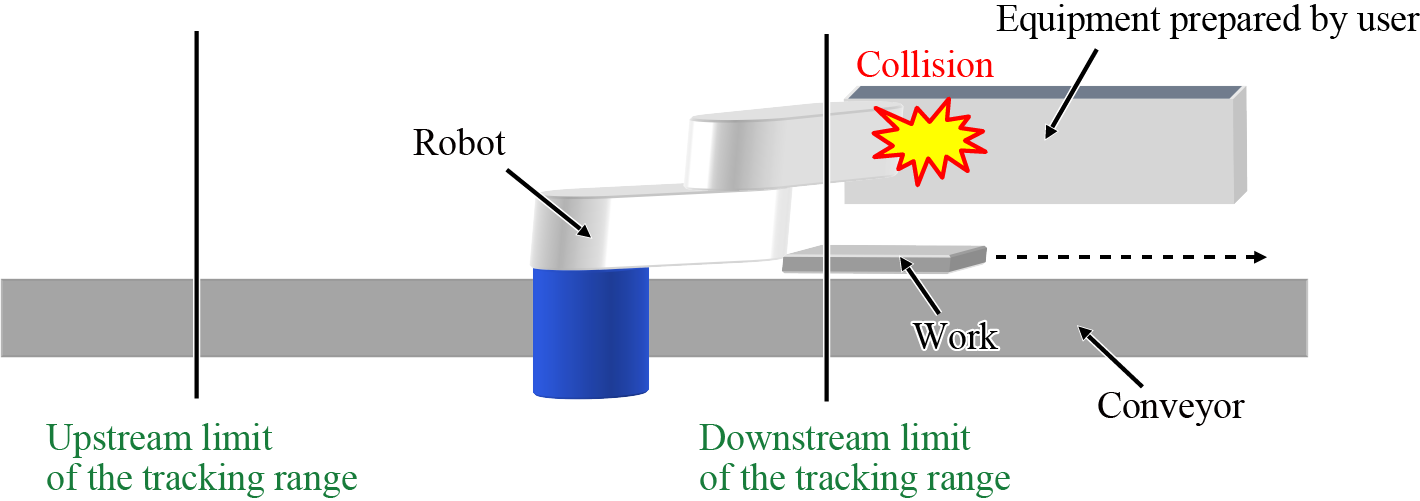

If the braking distance margin for the Downstream limit of the tracking range is insufficient, a robot and equipment will collide as the figure below shows.

Please pay attention to avoid collisions with equipments placed behind the Downstream limit of the tracking range. It is recommended to perform collision check by using Area function to prevent unintended contact between robot and equipments.

When you perform collision detection, please take enough margin for braking distance into account since robots cannot halt immediately after collision detection.

To avoid interference with the equipment, the following ways are available other than Area function.

- Check whether a workpiece passes the downstream limit using TrackInRange command.

- Monitor the current position of a workpiece using TrackCurPos command.

- Figure out the time to reach the downstream limit using TrackArrivalTime command.

ID : 2276